If How to Make a Capacitive Spot Welder:

Tips for Novices

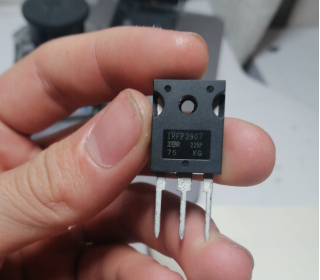

1. Choice of MOSFET: Select a MOSFET with high instantaneous current for the principle of the spot welder is instant low voltage and large current discharge, such as IRFP2907 with an instantaneous current of 209A and voltage tolerance of about 75V, which is sufficient for a 2.8V 3000F capacitor set-up.

2. Choice of Farad Capacitor: Farad capacitors are recommended for their large capacity, which increases the number of spot welding times, unlike normal capacitors whose maximum capacity is only around 40,000uF, and 1F=1000mF=1,000,000uF. Thus, it's appropriate to use 2.8 (2.7 is also applicable) V, 3000F farad capacitors with a voltage of 5.6 (5.4) V and 1500F.

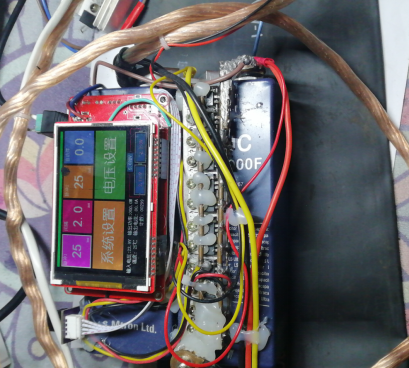

3. Choice of Control Board: Choose a control board with an LCD screen that supports 20A constant current charging, which can be selected according to individual needs on the website

(Note: these control boards do not come with MOSFET boards, which require manual assembly; recommended MOSFET type: IRFP2907).

4. Selection of Spot Welding Output Line: Use 16 square copper wire (or silicone wire for better quality) for currents of approximately 500A or 32 square wire (or larger) for higher currents, keeping the output line length around half a meter to avoid lowering the current due to increased resistance.

5. MOSFET Board Assembly: As this is a short-time discharge, it's unnecessary to consider the difference in current between MOSFETs, so all of them can be connected in parallel - G to G, D to D, and S to S. Use 12 MOSFETs for large currents or 24 MOSFETs or more for even greater currents, depending on individual needs.

(Note: Leave a 500A reserve when designing the board for the maximum output current, as this ensures the board does not explode.)

Friendly reminder for novices: Use thick input/output wires and copper strips for connections between MOSFETs (size depends on required current). It's important not to skimp on materials to avoid issues such as sparking, overheating, insufficient current, and false welding. If you don't have a device to measure instantaneous current, use the following formula: (Voltage before welding - Voltage after welding)/timecapacity=average current during welding. For example, for a 5.6V voltage before welding, 5.4V voltage after welding, 10ms time, and 1500F capacity, (5.6V-5.4V)/0.01s1500F=30,000A.

(Note: this is a simulated number for understanding purposes, as 30,000A current is unlikely to occur.)