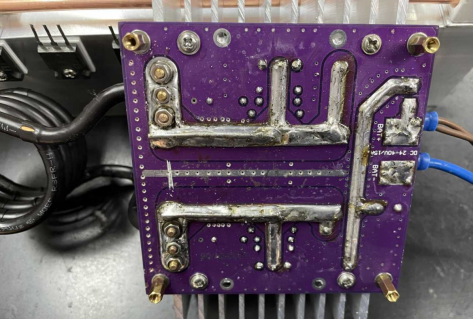

If you use a self-made board to make two 1000W amplifiers, but the section of the circuit that connects the resonant capacitor and the inductive coil overheats severely, adding two 2.5mm and two 1mm silver-plated wires to the circuit doesn't improve the heating much. So you have to change to a tent structure and increase the power to 3000W with six parallel tubes. The MOSFETs were initially imported and salvaged IRFP250A, but using them in parallel failed because the parameters of the salvaged tubes were inconsistent, resulting in uneven opening of the MOSFETs. So they were replaced with new Infineon IRFP260M MOSFETs.

The board for the 1000W amplifiers was made using PCB, and the MOSFETs used were imported and salvaged IRFP250As.

The PCB resonant capacitor is connected to the inductive coil, and is opened with two 2.5mm and two 1mm silver-plated wires.

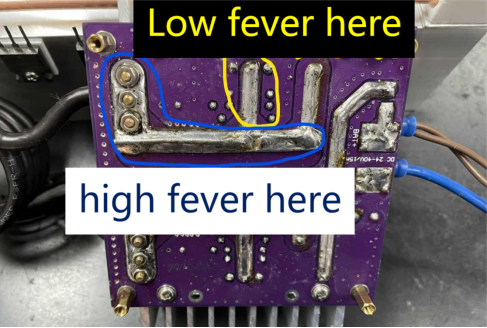

The part of the PCB that generated heat is shown in the diagram, with the MOSFETs and the section of the circuit that connected the resonant capacitor and the inductive coil marked with yellow and blue circles respectively.

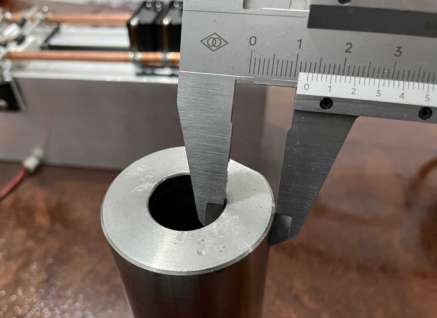

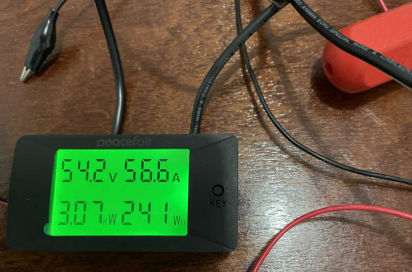

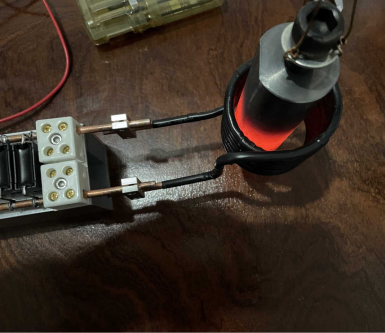

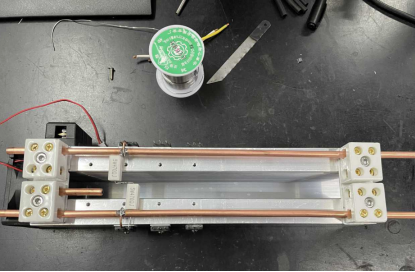

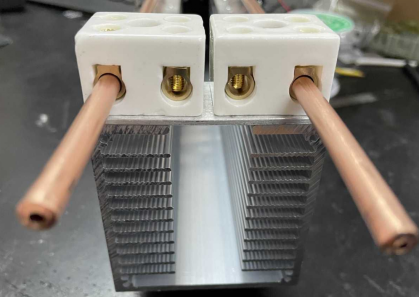

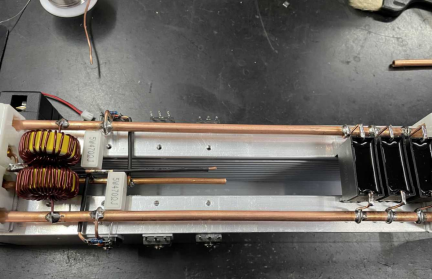

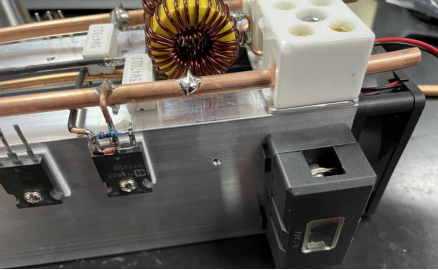

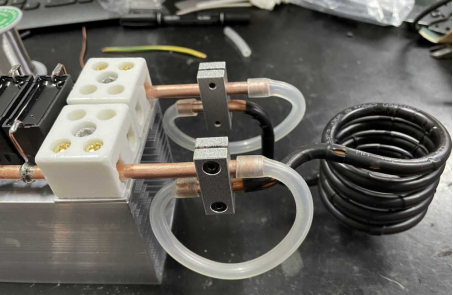

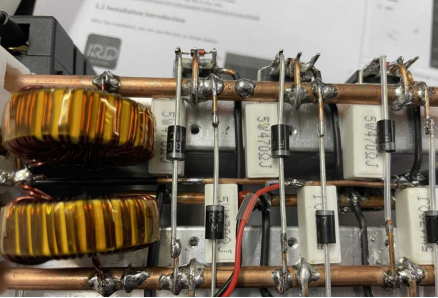

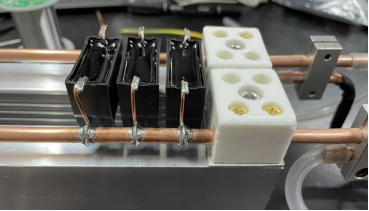

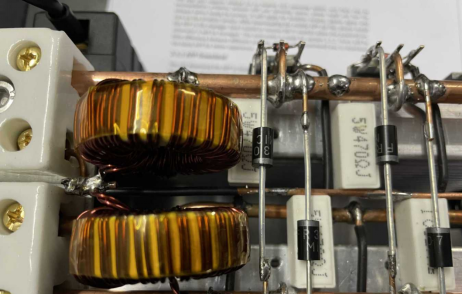

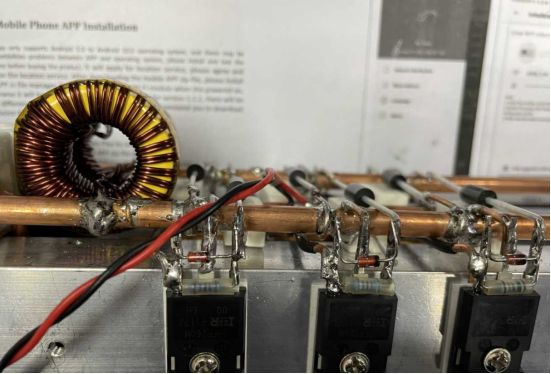

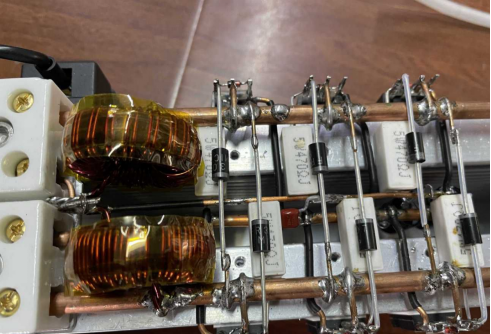

Starting from scratch, a tent structure was used with six parallel tubes. The inductive coil used 1x6mm purple copper tube, and a T130-26 iron powder magnetic core was initially used for the choke coil. A 1mm diameter enameled copper wire was used for winding in parallel. However, the magnetic core generated a lot of heat, so two magnetic cores were connected in parallel, but the heating problem still persisted, even under no load conditions. Finally, the magnetic core was changed to a silicon-aluminum-iron core with the same diameter as the iron powder core, and the wire diameter was increased to double 1.2mm. The tent structure was placed on a 70x70x300 aluminum alloy radiator for heat dissipation.

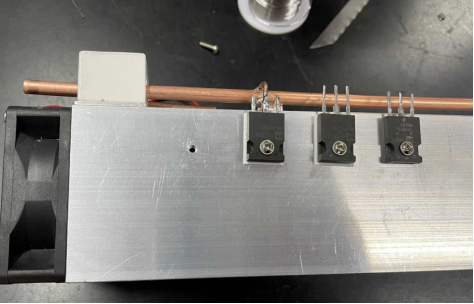

Removal tube for MOS

Silicone tube for water cooling system

T130-26 Iron powder core choke coil

Three 0.33uF resonators in parallel

The MOSFETs were replaced with new Infineon IRFP260M MOSFETs.

The choke coil's magnetic core was replaced with a silicon-aluminum-iron core with the same diameter as the iron powder core.

A 4.5cm hollow iron rod was heated to red-hot in about 90 seconds, with a maximum power output of 3000W.