How can you DIY a small spot welding machine using a microwave oven transformer? The modified transformer only has a power of 700W, which is a bit low, but it gets the job done.

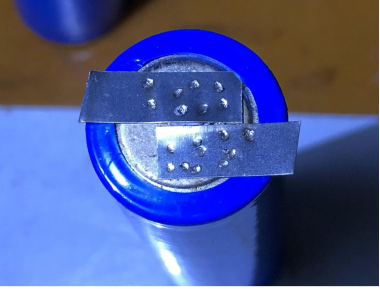

To begin, use a hacksaw to cut open the secondary side of the transformer. The coil is made of copper, so remove the secondary coil completely. Gather multiple strands of soft copper wire, totaling approximately 50 square millimeters in cross-sectional area. Wrap the copper wire with high-temperature adhesive tape and then cover it with heat shrink tubing. With a 10mm diameter, only two and a half turns of the copper wire are needed to fill the slot. When tested with power, the secondary voltage is only 2.6V, which is a bit low, but as long as the current is sufficiently high, it will work. The no-load power is around 75W. Purchase a 40A controller online and use a 12V power supply transformer that you already have. Modify the casing of the spot welding machine. The process goes smoothly, and it is a success on the first attempt. When testing the machine, the welding current only needs to be set at 50%, and it produces very strong welds on 0.15mm thick nickel-plated steel strips attached to batteries.

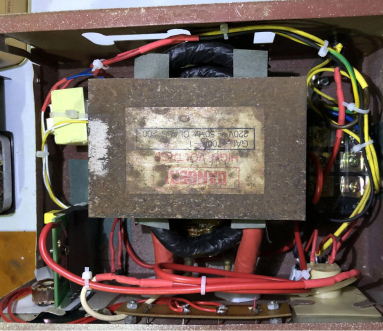

Spot welder, transformer

Saw off transformer secondary

Transformer secondary cross section

The secondary coil is copper wire

Clear secondary

40A current time control board

Internal wiring of spot welder

Housing panel

The welding pen is made using a 3mm copper core, and its size can be adjusted according to preference.

Here is a picture showcasing the spot welding effect:

In summary, converting a microwave oven transformer into a small spot welding machine is a practical and accessible DIY project. Despite its lower power output of 700W, it remains effective for various welding tasks. By following the steps of cutting, removing, and replacing the secondary coil with multiple strands of soft copper wire, combined with a 40A controller and modified casing, you can create a reliable welding setup. The adjustable welding pen, made from a 3mm copper core, provides secure welds for materials like nickel-plated steel strips on batteries. This DIY spot welding machine offers a cost-effective solution for your welding needs.