Explore a comprehensive guide on constructing a state-of-the-art DIY spot welder using super capacitors. This guide emphasizes safety, efficiency, and user-friendly controls, making it an ideal project for welding enthusiasts.

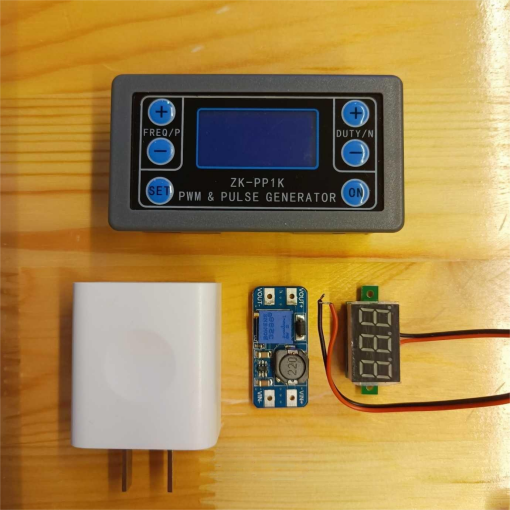

Materials Needed:

l Two super capacitors

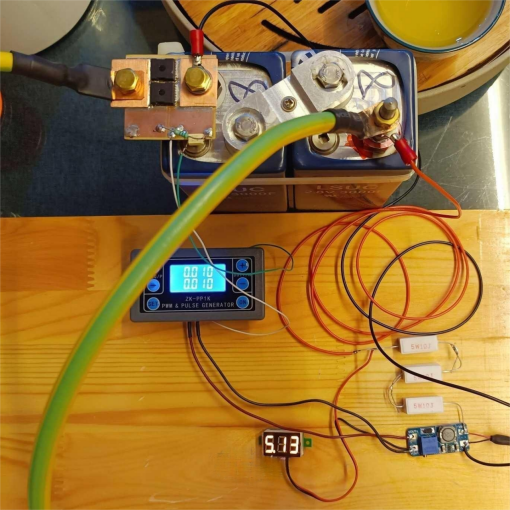

l One pp1k module

l One boost module

l One mobile phone charger (5V2A)

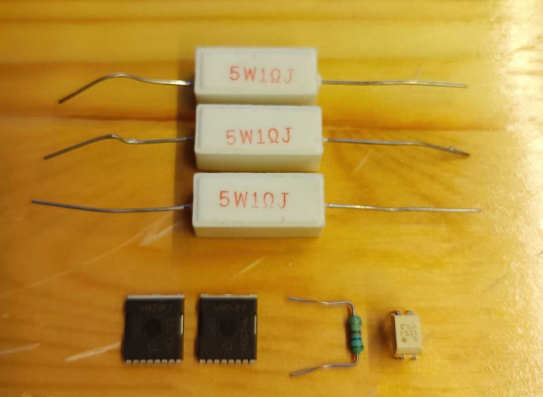

l Five resistors

l One optocoupler

l Two mosfets (mos4n04r7)

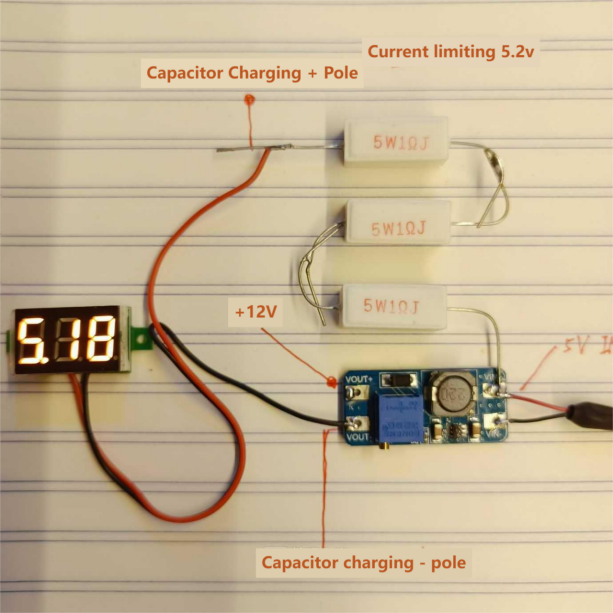

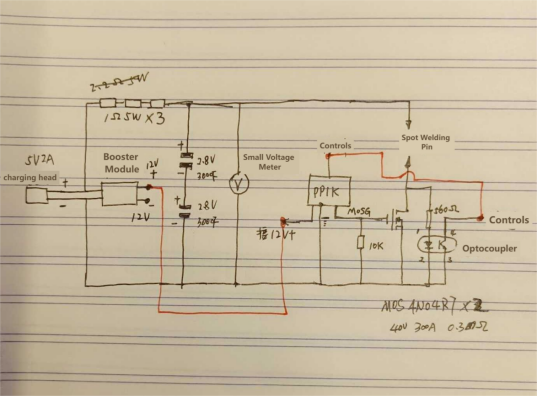

Power Supply Setup:

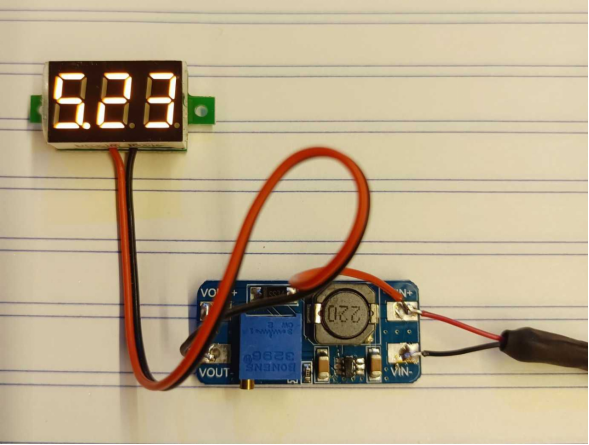

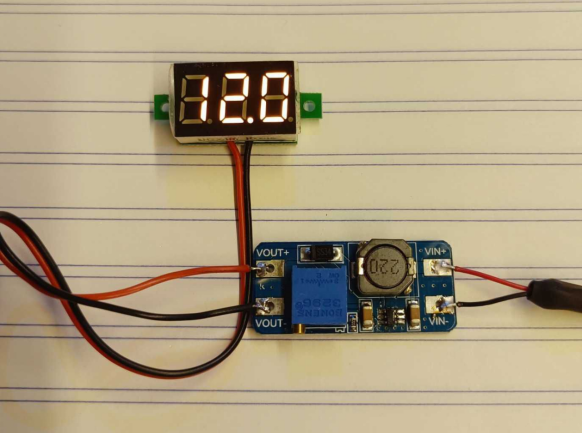

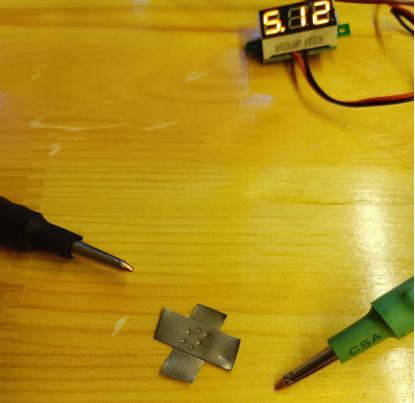

Begin by testing the charger voltage (5.23V) and adjusting the boost module to achieve a 12V output.

Connect the capacitor charging current-limiting resistor and ensure safety by using a charger with a voltage below 5.4V and an output capacity of 2A.

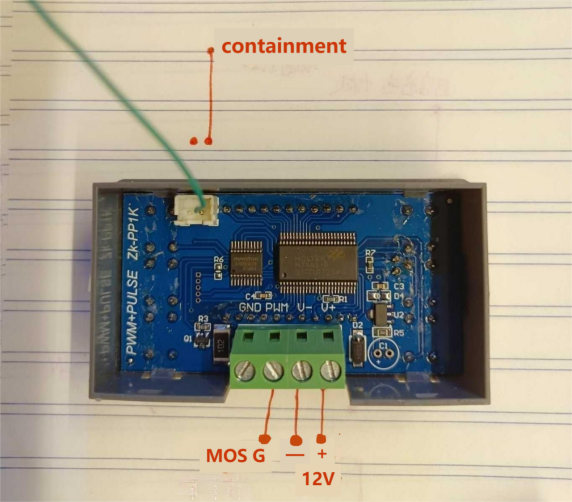

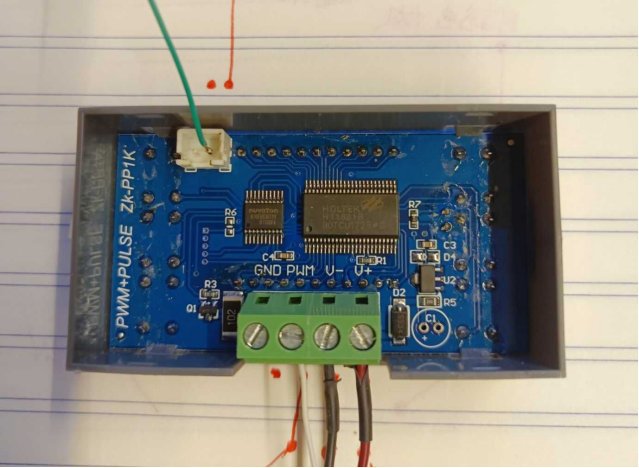

Welding Machine Control:

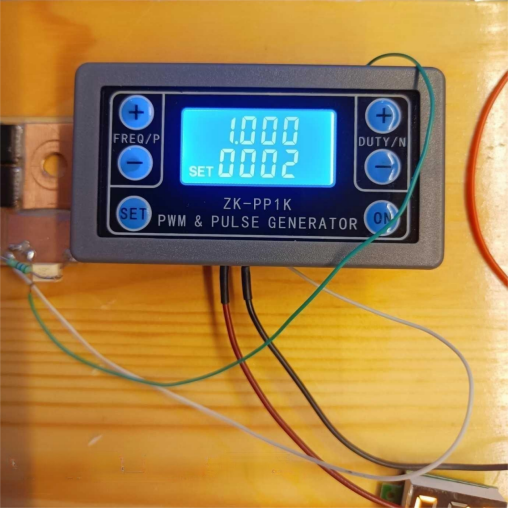

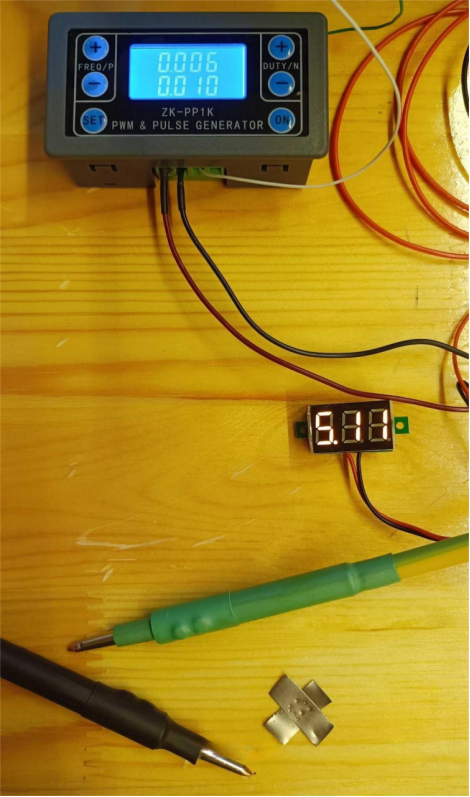

Effortlessly configure the pp1k module for welding control.

Enter pulse mode by long-pressing the "set" button for 6 seconds. Adjust pulse width (10ms) and pulse interval (10ms) using the +/- keys.

Navigate to page 2 for additional settings such as delay time and pulse repetition.

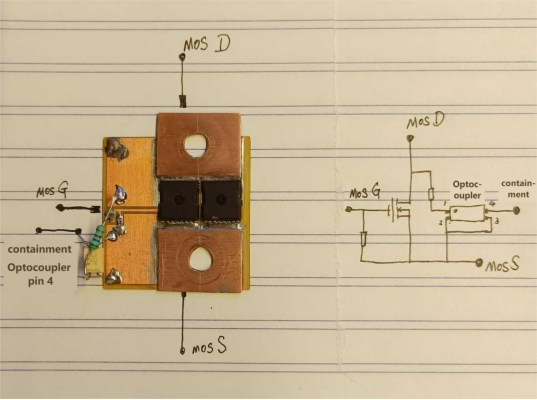

Mosfet Integration:

Select and connect the appropriate mosfets, such as mos4n04r7, and incorporate an optocoupler for optimal performance.

Follow the diagram to connect the modules, setting parameters like a 6ms pulse width, 10ms interval, and 2 pulses. Achieve success with a 1-second trigger delay.

Conclusion:

Cap off your DIY spot welder project by considering long-term use. Include a balance module on the capacitor for extended durability and functionality. This detailed guide ensures a seamless construction process, combining safety, precision, and innovation for an efficient DIY welding solution.