Introduction:

Discover efficient methods for crafting battery packs without the need for specialized machinery. This comprehensive guide outlines step-by-step procedures for manual casing fabrication, along with crucial testing protocols to ensure optimal performance. Whether you're a novice or experienced enthusiast, these techniques empower you to customize battery configurations tailored to your specific requirements.

Key Points:

· Manual Casing Fabrication: If you don't have a 3D printer or CNC engraving machine, you can manually handle the casing part.

· Modular Expansion: The goal is 6S, but typically you won't need that many. If you currently only have up to 3S batteries on hand, you can start with a 4S setup. If needed, it can be easily expanded later. Once you've sorted out the casing and wiring, the remaining parts can be handled by the corresponding factory.

· Regulatory Precision: Use an adjustable voltage and current regulating DC module as the main regulator.

· External Power Supply Integration: The power module is placed outside, and power can be supplied using idle laptop power supplies, ATX power supplies, etc.

· Comprehensive Testing: The batteries are the original matching batteries for the Wei Li quadcopter.

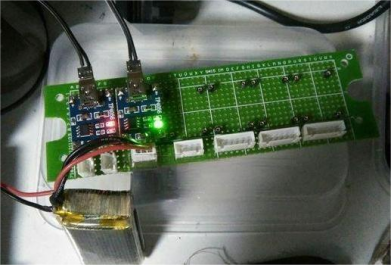

· Adopt independent power supply. There have been significant adjustments in space arrangements, and all charging modules have been externalized. The testing will sequentially display battery type (number of S cells), voltage of each cell, and total series output voltage.

· Here's a test with a single idle cell phone battery, i.e., 1S:

· This is the measurement of the original 2S battery of the quadcopter:

· The test of the largest original 3S battery, 3cE correctly identifies the battery type as 3S or 3 series.

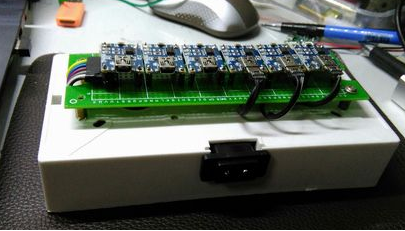

· Done. Here's the back:

· Future Scalability: Because the largest battery mentioned in the article is only 3S, connections for 4 to 6 channels need to be supplemented later on. The rest is just mechanical processing on the casing, which can be done independently.

Conclusion:

Empower yourself with the knowledge and techniques presented in this guide to create custom battery packs with precision and confidence. By embracing manual assembly methods and adopting thorough testing protocols, you can unlock endless possibilities for powering your projects.