The exhaust fan runs 24 hours a day. The regular motor has a power of 40 watts, which consumes a lot of electricity. However, after converting it to a Nidec outer rotor brushless DC motor, the power consumption is significantly reduced for the same airflow. The brushless motor, including the DC power converter, only consumes 11 watts.

In environments with high humidity, keeping doors and windows closed with the exhaust fan off makes the air quality poor, which can be uncomfortable for people. Turning on the exhaust fan brings in a lot of moisture. To mitigate this, you can adjust the fan speed to reduce the amount of incoming air, significantly improving the situation with water vapor. However, adjusting the motor speed typically requires moving the power supply back and forth, which is inconvenient for long-term use. To solve this, you can add an adjustment and display to the converter. The voltage can be adjusted between 9-16V, and a digital voltmeter can be installed.

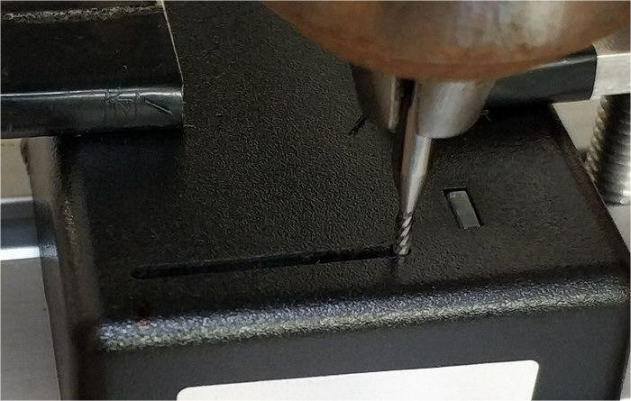

If you don't have a CNC machine or milling machine, you can still use a simple bench drill with a regular cross slide.

Drilling produces a lot of debris, so it's important to clean it up with a vacuum cleaner promptly.

You'll also need to drill a hole for a potentiometer, and using a milling cutter works best for this.

Try installing a digital display. It's okay—better than doing it manually.

The digital display used here is 0.28 inches.

At first, the display may appear a bit harsh on the eyes, but applying a layer of matte film improves it significantly.

Here's the result after completion.

This setup allows the fan to be fixed in place for use.

The brushless motor is very practical—at 9V, the fan rotates at about two revolutions per second, while at 16V, it runs like a blower. Experience shows that this brushless motor can adjust its speed without using its speed control terminal.