If you're into DIY electronics, this article might interest you. Many people who do DIY electronics often start by building the basic framework, and while a well-planned soldering layout can be aesthetically pleasing, it can also come at a high cost.

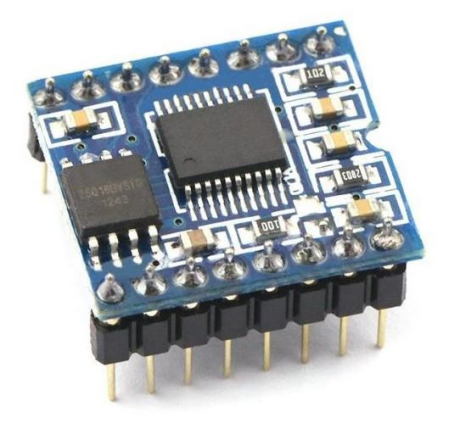

This means the components aren't being reused effectively. Today, there are many ready-made modules that can be used directly. In fact, the reason many circuits are modular is to simplify various application designs and allow for reuse. A quick online search reveals a wide variety of functional modules available.

Of course, using pre-made modules does have its downsides, such as size, especially height (overall thickness), which increases significantly. This is because most pre-made modules use pin headers and female headers for connections, which inevitably adds to the overall thickness.

Though there are modules with reserved "stamp holes," they are still quite rare.

However, this also requires that the boards you're connecting have corresponding stamp hole connectors.

Pin header and female header connections are easy to plug and unplug, and have a high reuse rate. But just the thickness between the boards can be around 10mm. Board-to-board connections with stamp holes are ideal for keeping the boards at the same level, but they are not easy to disassemble, and their reuse rate is low.

The method of directly soldering the pin header onto another board (board-on-board) has been around for a while, but this method is also not very reusable. Once it's soldered, it’s difficult to disassemble. Nowadays, it's easy to design boards with double-sided pads, but removing solder to disassemble them can be a challenge.

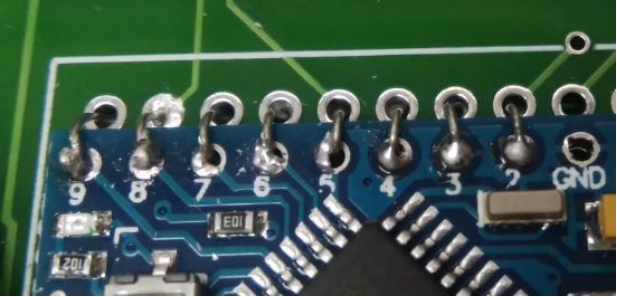

So, what method should you use? You can add extra pads for board-on-board stacking and binding during the soldering process. While this method may not be the most aesthetically pleasing, it makes it easy to remove the module, and the thickness can be minimized.

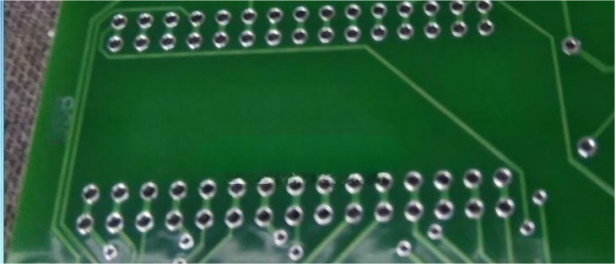

Below is a PCB layout for a certain module on the motherboard in a DIY project.

With this method, there's no need to solder pin headers onto the module. When soldering, just apply a small amount of solder to the pads, enough to secure the connection.

Disassembly is easy: simply cut the binding wires and use a soldering iron to clean up the pads. This method has a very high reuse rate.

That's it!