If someone is interested in DIY-modding an SVC-3000VA AC voltage stabilizer, this article may be worth a look.

The SVC-3000VA stabilizer provides two output voltages: 220V and 110V, which makes it very convenient for many tools. Back when household voltage was unstable, appliances like air conditioners and refrigerators often failed to start due to low voltage, so this device was extremely popular at the time.

Its working principle is very simple: it uses an autotransformer paired with a control board that monitors the input voltage. When the voltage rises too high, the board outputs a control signal to a DC motor, which drives a reduction mechanism to rotate the central carbon brush and lower the output voltage. Once the control board detects that the voltage is back within the normal range, it stops the motor. If the voltage is too low, it reverses the motor to raise the voltage.

If someone owns the same stabilizer but finds that the motor has become weak and can no longer adjust the output voltage automatically—and the motor terminals show less than 3V—keep in mind that this motor is actually a 12V motor. Because the load is relatively heavy, the motor fails to turn under such low voltage. However, if the motor is removed from the device, it can spin under no load, though not ideally. When supplied with a full 12V, it runs normally. If this issue sounds familiar, the device can be opened and inspected following this article.

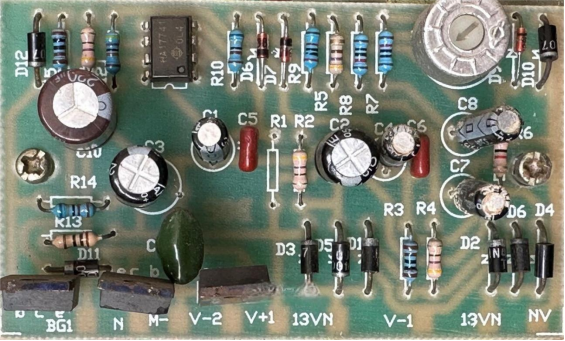

As shown below, this is the front (component side) of the control board.

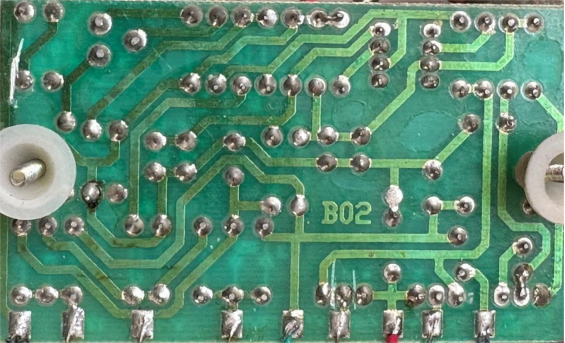

As shown below, this is the back of the control board.

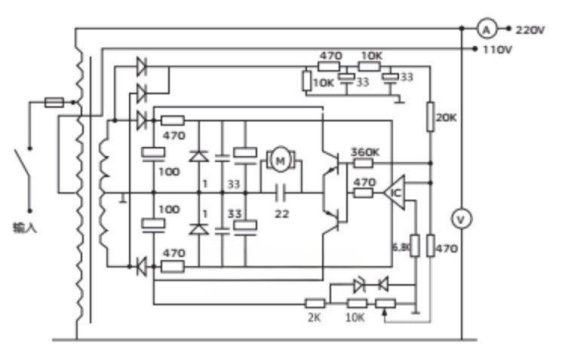

The schematic can be found online and is almost identical to this one. The version shown below adds one extra transistor.

The circuit is very simple. The front end is a full-bridge rectifier that outputs ±22V to two power diodes. After passing through a resistor and a zener diode for regulation, the voltage becomes a ±12V dual supply for the 741 op-amp. The op-amp is not wired as a basic comparator, but rather as a Schmitt trigger (or hysteresis comparator). One input is connected to the power midpoint, while the other input is connected to a network of resistors involving the negative regulated voltage and the rectified positive voltage. A potentiometer allows that input to be adjusted. Because the negative supply is fixed and the positive supply is proportional to the AC voltage from the auxiliary winding, the AC output voltage is therefore proportional to the input voltage of that op-amp pin. The op-amp output then drives a pair of power transistors configured as a half-bridge to deliver current to the motor. Using a hysteresis comparator prevents the motor from constantly twitching around the switching threshold.

However, because the op-amp behaves like an amplifier in this configuration, its output ranges from –12V to +12V. When the output is within ±3V, the motor cannot turn and becomes stalled. The power half-bridge carries more than ±22V, so the power transistors dissipate significant heat. When the motor is stalled, they even become hot to the touch.

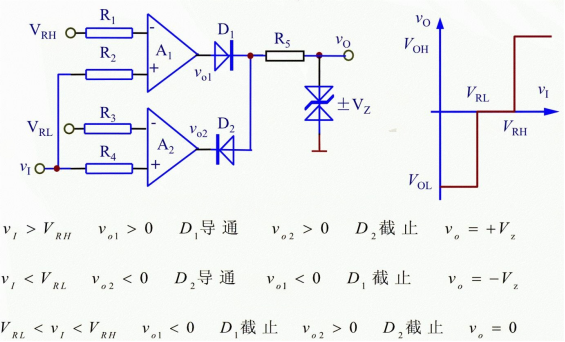

To address this, the circuit can be modified by switching to a true comparator configuration. In that case, the output would always be ±12V without any weak 3V region, and the motor would run reliably. However, a typical comparator only provides two states—high and low—which correspond to forward and reverse motor rotation. A third state is needed: motor off. For that, a tri-state comparator is suitable, as shown in the circuit below.

This tri-state comparator uses two comparators with different reference voltages—one high and one low. When the input voltage exceeds the upper reference, the output goes high; when it falls below the lower reference, the output goes low; when it sits in between, the output is zero. This matches the requirement exactly. The original IC is a 741, with pin 4 as the negative supply, pin 7 as the positive supply, and pins 2 and 3 as the inputs. It can be replaced with an LM358, which also uses pins 2 and 3 for inputs and pin 4 for negative supply, but uses pin 8 for positive supply. Simply cut the old pin-7 supply trace and reroute it to pin 8, then rewire the unused pins according to the tri-state comparator circuit. Only two jumper wires are needed to complete the modification.

Additionally, on the original sensing circuit, the resistor from the potentiometer to the positive supply should have its copper trace cut and a removed 470-ohm resistor inserted in series. This creates two different reference voltages for the high and low thresholds. Several electrolytic capacitors in the detection circuit should also be checked. If the 35V 33µF capacitors shown in the picture have degraded, they can be replaced with 16V 100µF capacitors. The actual voltage in that section does not exceed 16V, so it remains safe.

After the modification, whenever the output voltage drifts from 220V, the motor consistently receives the full 12V and runs strongly. Once the voltage reaches its threshold, the motor voltage immediately drops to zero. The power half-bridge no longer heats up. Measurements show that the dead-zone voltage span is about 13V, which is a bit large. Calculations indicate that replacing the 470-ohm resistor with a 200-ohm resistor would reduce the dead-zone to about 5V, allowing the final output to regulate within ±2.5V of 220V—very reasonable. If the dead-zone is too narrow, unnecessary switching may occur.

With the modification complete, the adjustment speed becomes very fast. Once the target voltage is reached, motor current drops to zero, and the power transistors no longer heat up. The original design had no heatsink and would feel slightly warm; now it stays completely cool, which improves reliability.

If the device's input/output terminals are inconvenient, the connectors can be replaced with built-in sockets—an American-standard outlet for 110V and a Chinese-standard outlet for 220V. The input line can remain wired directly to the terminal block. This way, the output can be used either through the terminal block or through a plug-in power strip.

Finished.