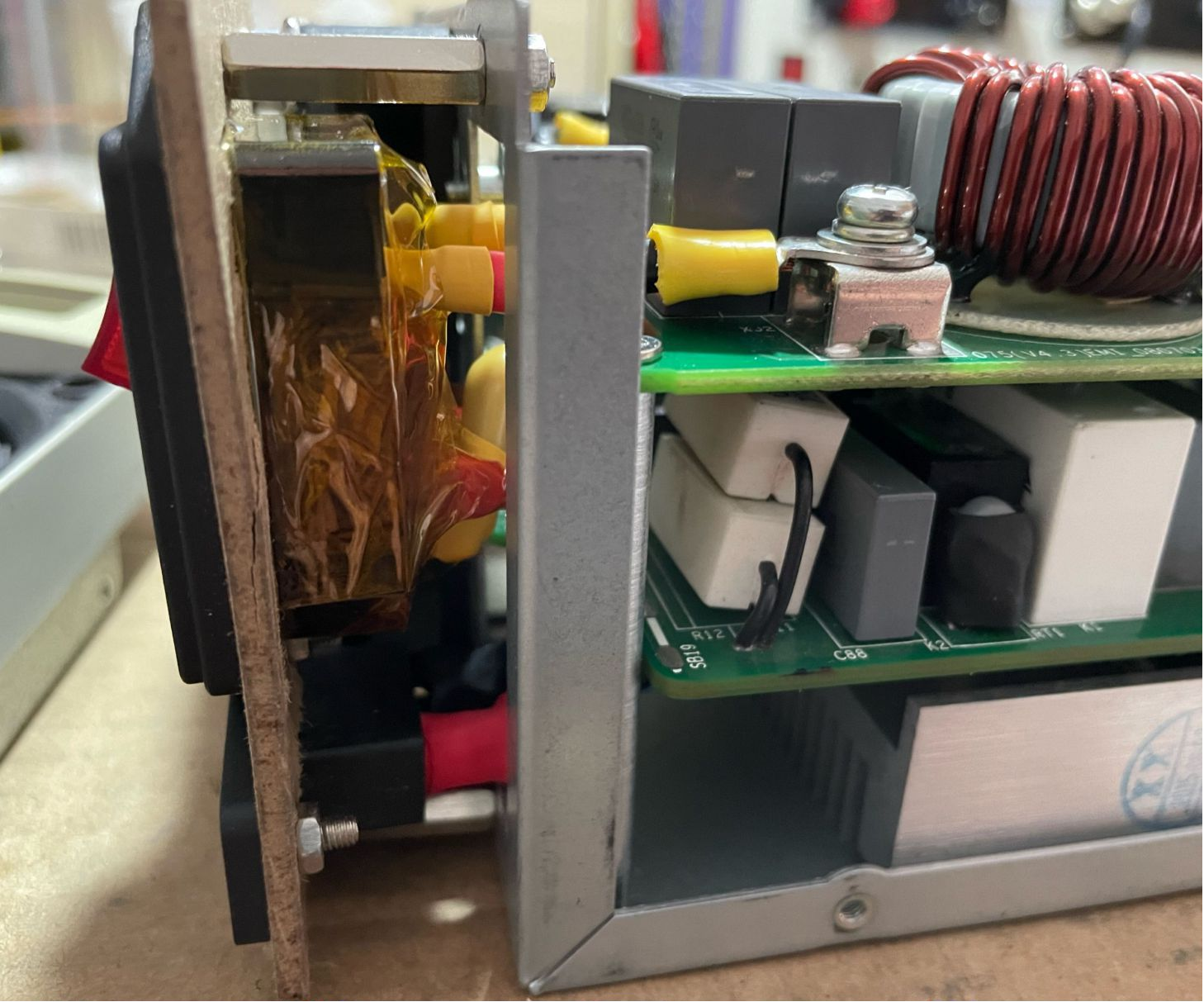

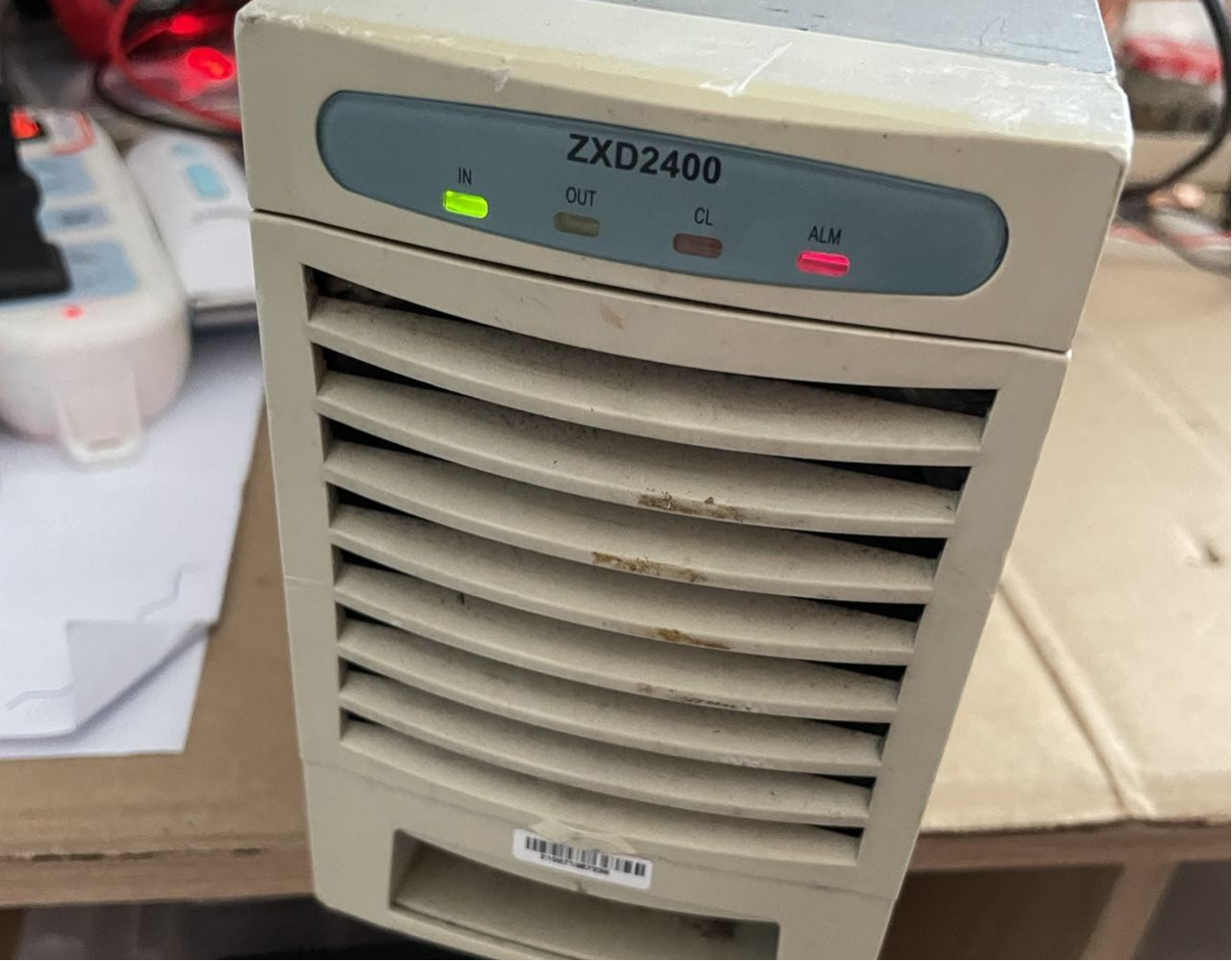

Bought a used ZTE 2400 (4.3) power supply from a second-hand platform for ZVS power supply. When testing, the power indicator lit up red, but the fan did not turn, and there was no output. Upon inspection, it was found that during transportation, the fan was jammed due to a deformation caused by a collision on the upper right corner of the fan's casing. The fan rotor's fixed foot was also broken. After adjusting the deformation and using hot-melt glue to fix the fan, the machine operated normally. However, after running for about five minutes without any load, the machine exploded with a loud bang.

Instead of returning the product, the person decided to repair it themselves. When connecting the machine to AC power again, the power indicator did not light up, and the fan did not turn, and there was no output. After checking, all of the large tubes on the board were fine, and the bridge pile was also fine. The 450V large electrolytic capacitor had a direct current voltage of 300V. The auxiliary power supply was suspected to be damaged, and after further investigation, it was found that R38 and R82 resistors were visibly burned out.

After replacing R38 and R82 with resistors of the same parameters, the machine still could not be turned on, and there was no response. Testing the 450V large electrolytic capacitor revealed that it had a capacity display of 0L, which was thought to be broken. However, after removing it for measurement, it was found to be 410UF, and the only problem was a decrease in capacity of about 60UF.

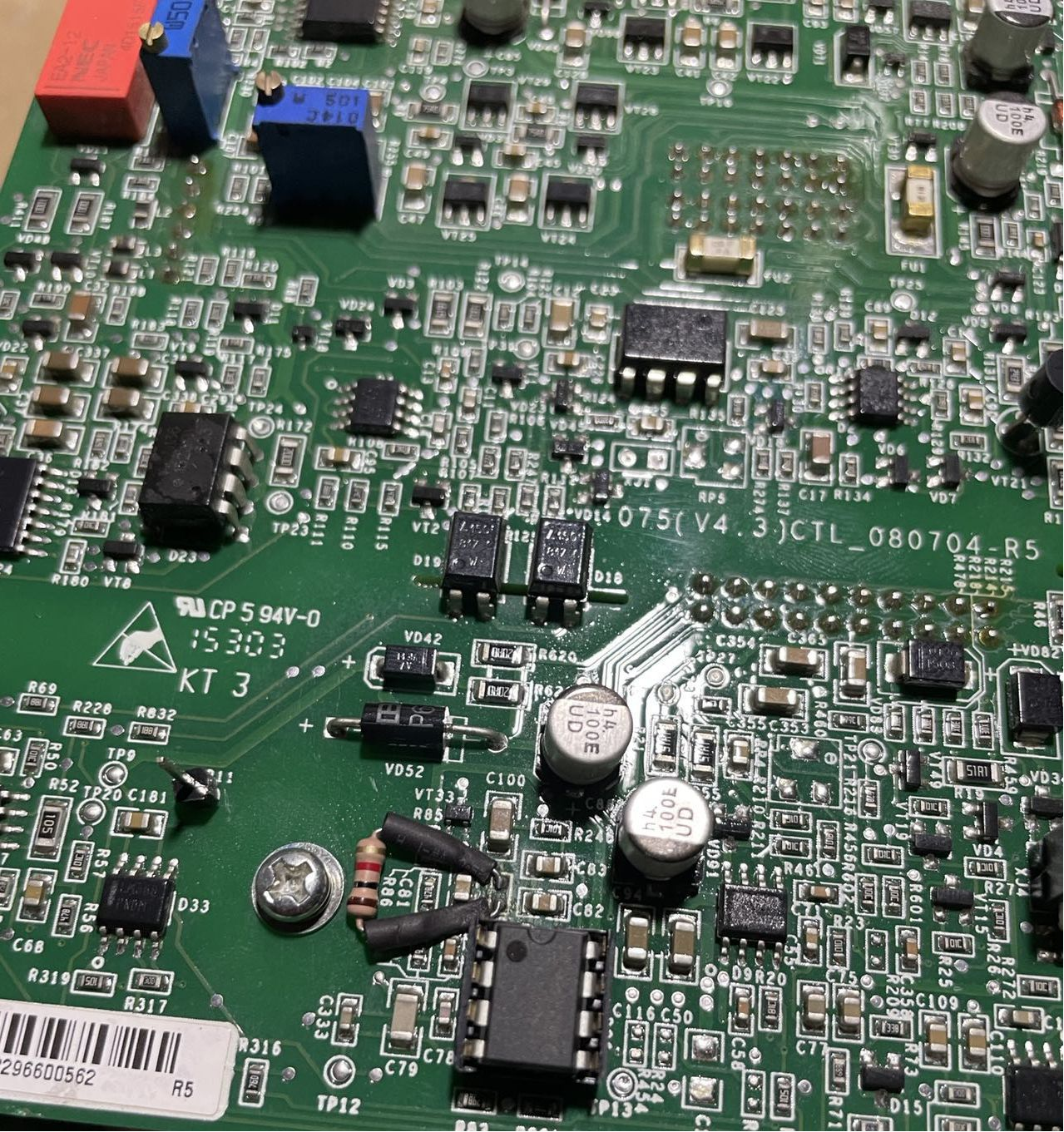

Upon further inspection of the auxiliary power supply section, it was discovered that VD36 and VT5 were shorted, and R30, which should have been a 1.5-ohm resistor, had become a 27-megohm resistor. After replacement, there was still no response after powering on.

Finally, TL3844BP was replaced, and after powering on again, the long-lost sound of the fan was heard, the indicator light lit up, and there was output voltage. The power supply was finally back to normal.

An 8-pin chip socket was added at the 3844 location for easy replacement of damaged chips in the future.

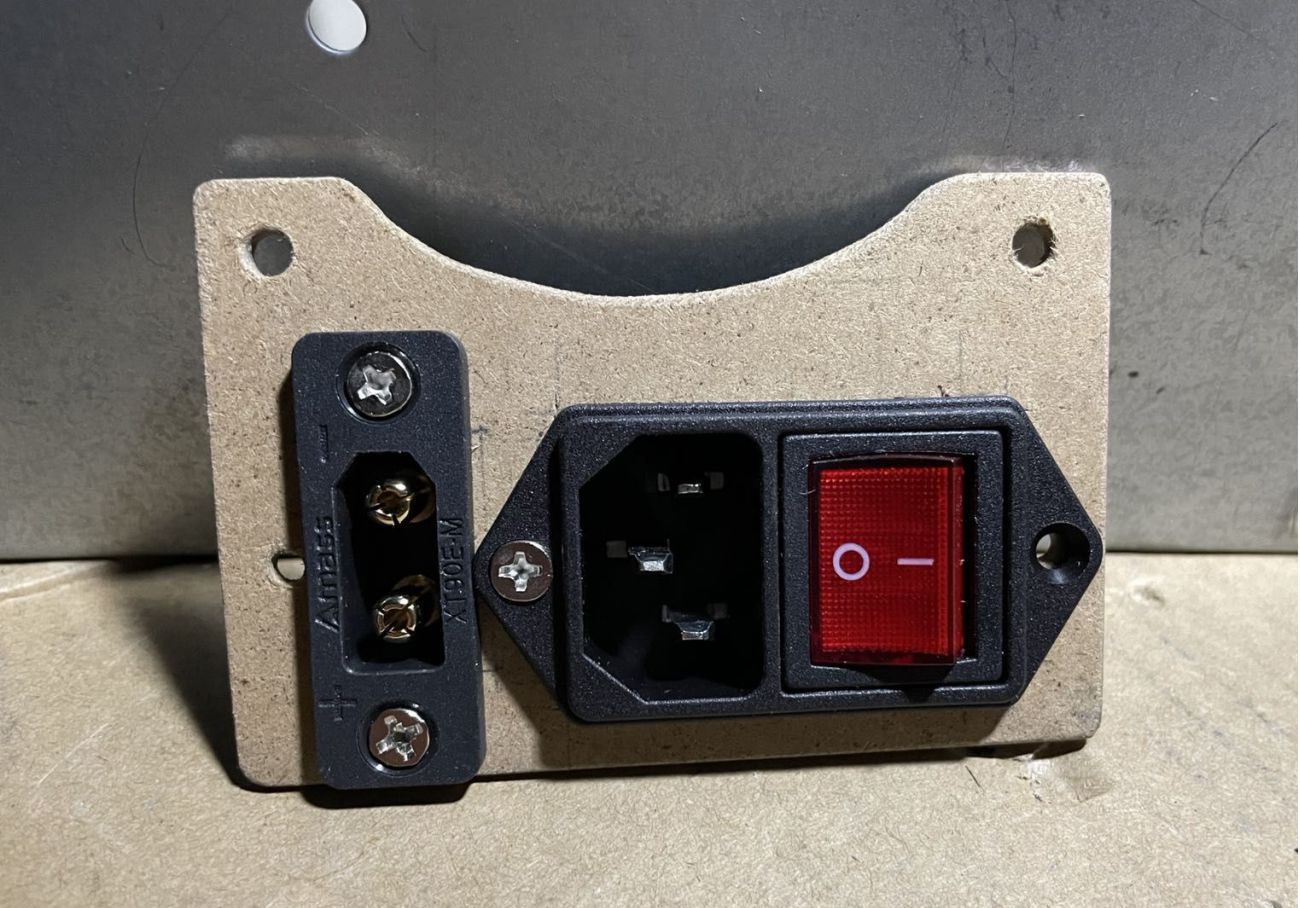

Finally, a tail plug was made using a small piece of wood, a cross-shaped socket, a switch, and an XT90 terminal since the original tail plug could not be used.

In summary, the reason why several components were damaged was probably due to the deformation caused by the collision on the upper right corner of the fan's casing, which caused the fan to jam during operation. Although it was processed, there was still obvious friction noise during the operation of the fan, which caused the current of the auxiliary power supply to increase, leading to the damage of R38, R82, R30, VD36, VT5, and TL3844BP. After replacing all these components, the power supply returned to normal.

During testing, the power indicator lit up red.

When replacing damaged components, using multiple resistors in series and parallel instead of the original resistor is also beneficial for heat dissipation.

Since there were no surface mount resistors available, the original surface mount resistor was replaced with a color ring resistor and a 3844 chip socket was added.

The repair was successful.

A tail plug made from a small piece of wood is simple and practical, and saves the cost of buying one.