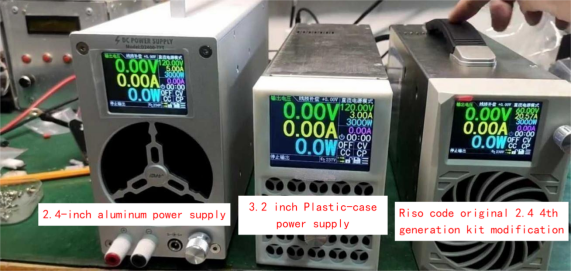

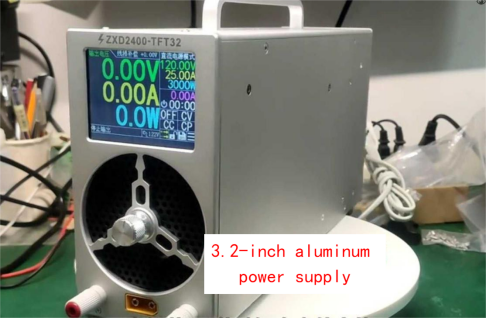

In the modified version of the ZTE 2400, there is a 3.2-inch large screen. It comes in both an aluminum alloy version and a regular plastic shell version. If you're interested in upgrading to the 3.2-inch aluminum alloy version, then you might want to take a look at this article.

Even if you have a brand-new power supply, before the modification, you should open it up to check for dust buildup and ensure that everything is functioning properly when powered. Generally, a new power supply shouldn't have much dust inside, the fan should be clean, and the casing should be normal. The internal power function should also be normal.

Here are some things to keep in mind during the 3.2-inch modification process:

1. When you buy the screen kit, don't peel off the protective film on the screen right away. It's better not to remove it during soldering as it could scratch the screen.

2. When soldering after purchase, the older version requires soldering the screen and the ribbon cable and adapter board that comes with it. Afterward, you need to remove the original screen and solder its ribbon cable to the adapter board. If you're unable to do this yourself, consider seeking help. Since the equipment is quite expensive, especially for the 3.2-inch aluminum alloy version, there's a risk of damaging the screen or needing costly repairs if there's a short circuit during the soldering process. Therefore, careful consideration is essential.

3. After soldering, don't rush to put everything back in the case. Test the device by powering it on first. This acts as a self-check, allowing you to address any issues beforehand. Otherwise, if you encounter problems after assembling the device inside the case, you'll have to dismantle it again, which can be time-consuming and might damage the screws.

4. If you're modifying the plastic shell version with a 3.2-inch screen, it's recommended to install the encoder first. Hold the encoder in place with your hand and press the button on the backside. The area where the encoder is installed on the plastic shell of the 3.2-inch version is also where the fan ventilation is located. This area has a hollow structure and is quite delicate. Therefore, if you assemble the outer knobs after securing the shell, you might accidentally damage the casing.

5. If you're assembling the aluminum alloy version, which has output ports on both the front and back, it's advisable not to use overly stiff wires. It's best to use silicone wires, as rigid wires might not bend easily, and the limited space could make handling them more difficult.