Transforming your vehicle's charging capabilities can be an empowering endeavor, especially when equipped with the versatile IPIP6538 fast charging boards. If you find yourself in possession of these components and in need of a vehicle charger solution, consider embarking on a DIY journey.

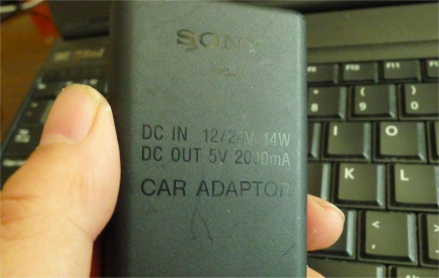

In this particular project, we'll be repurposing a PSP car charger. Despite its initial 5V2A output capacity, it has become outdated with the widespread adoption of fast charging protocols by modern smartphones.

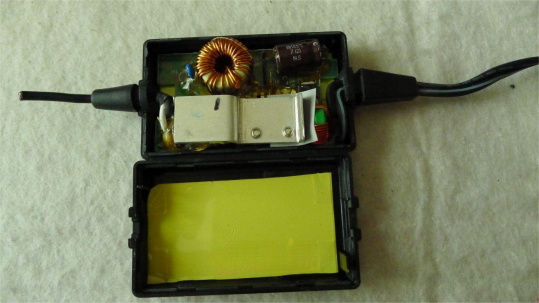

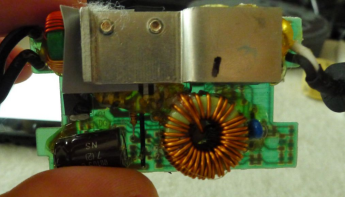

Inspecting the current output indicators, the inscription sticker on the back, and opening it up to examine the internals, you'll find that the design is quite intricate.

Notably, it incorporates EMI filtering for enhanced performance.

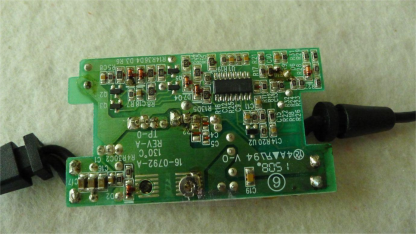

Unveiling the interior, one discovers a chip nestled on the reverse side, accompanied by two power tubes on the front.

While the original design may appear dauntingly intricate, the quality of materials employed underscores its durability and reliability.

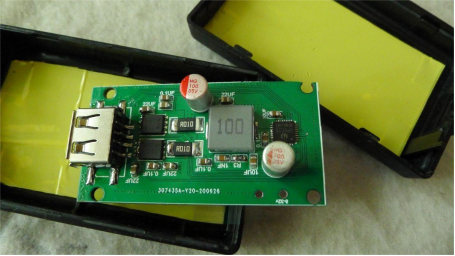

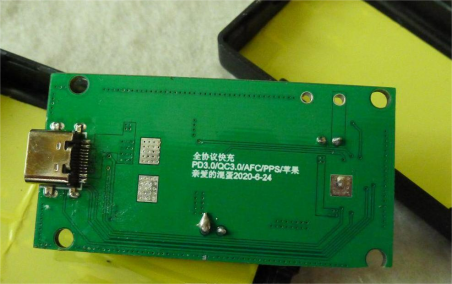

Housing the IP5358, a transparent and single-sided PCB serves as the backbone of this charging solution, offering compatibility with a staggering array of protocols, including PD3.0.

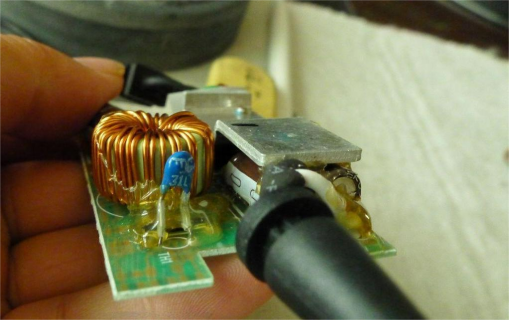

To effect modifications, repurposing a cigarette lighter plug proves instrumental, allowing for the seamless integration of residual wires.

Carefully disassembling the plug reveals distinct positive and negative contact points.

By threading the wires through the new plug and securing them via soldering, one ensures a robust connection.

While the original fuse is rated at 3A, the IP5358 boasts an impressive 45W output capacity. Despite this, its performance under a 12V supply peaks at 30W, rendering the original fuse adequate for our purposes.

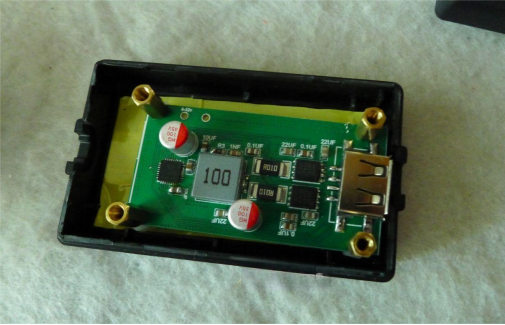

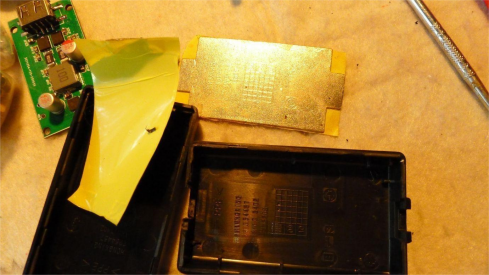

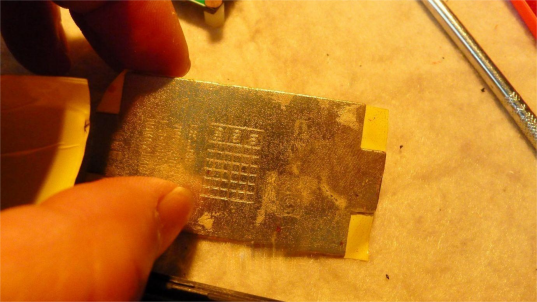

Securing the fast charging board within the housing necessitates drilling holes, revealing an unexpected feature: the original casing comprises dual layers of aluminum sheets for electromagnetic shielding.

Adapting to this revelation, we remove the aluminum layers, drill the necessary holes, and affix the circuit board securely in place.

Completing the installation involves sealing any gaps with silicone gel to safeguard against potential ingress of contaminants. Subsequent testing ensures seamless activation of fast charging, affirming the success of our endeavors.