In the electronic components industry, PTC thermistors are a highly regarded and essential component. They are renowned for their unique properties and diverse applications. This article delves into the definition, operating principles, characteristics, and advantages of PTC thermistors.

Catalog

IV. Characteristics and Advantages

I. What are PTC Thermistors?

PTC thermistors are resistors with a positive temperature coefficient, meaning their resistance increases with rising temperature. These thermistors are used as self-resetting overcurrent protectors and self-regulating heating elements.

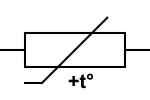

△ The smybol of PTC thermistor

II. Operating Principles

The operating principle of PTC thermistors is based on the direct correlation between resistance and temperature. As temperature rises, resistance increases, and vice versa. This characteristic allows PTC thermistors to serve as self-protective devices in circuits.

III. Types

PTC thermistors can be divided into two main types:

· Comprised of silistors: Silistor is a type of PTC thermistor based on semiconductor materials. It exhibits a linear correlation between temperature and resistance over a small range, making it suitable for use as a PTC temperature sensor.

· Switching Type PTC Thermistor: The switching type PTC thermistor has a highly nonlinear resistance-temperature curve. Initially, when heated, the resistance decreases until a certain critical temperature is reached. Once the temperature exceeds that critical value, the resistance increases dramatically. This type of PTC thermistor is widely used in PTC heaters and sensors. Polymer PTC thermistors, made from a special plastic, fall under this category and are often used as resettable fuses.

IV. Characteristics and Advantages

PTC thermistors offer the following characteristics and advantages:

· Overcurrent Protection: PTC thermistors can automatically limit the flow of current in a circuit during an overcurrent situation. When the current exceeds a preset value, the thermistor's resistance rapidly increases, protecting the circuit from damage and preventing overheating.

· Temperature Control: PTC thermistors monitor the temperature of circuits and devices. Once the temperature exceeds a certain threshold, they adjust resistance to control the flow of current and temperature, thereby preventing overheating and maintaining temperature stability.

· Motor Starting: PTC thermistors can control the current during the starting process of a motor, reducing motor strain and extending its lifespan.

· High Reliability: PTC thermistors are designed for stable and reliable performance over extended periods. They are durable and resistant to failures.

· Miniaturization: Modern PTC thermistors are compact and lightweight, making them easy to integrate into various small electronic devices. This aids in the miniaturization and lightweight design of electronic devices.

V. Applications

PTC thermistors find extensive applications in various fields, including:

· Home Appliances: PTC thermistors are used for overcurrent protection and temperature control in home appliances such as electric kettles, rice cookers, refrigerators, and washing machines, preventing overloading and overheating.

· Automotive Electronics: In automotive electronic systems, PTC thermistors protect circuits, monitor temperatures, and provide stable working conditions for automotive battery charging, motor control, and in-car electronics.

· Industrial Control: PTC thermistors are used in industrial equipment to monitor and control current and temperature, protecting devices from damage. They play a crucial role in motor control and factory automation systems.

· Communication Equipment: PTC thermistors provide overcurrent protection and temperature control in communication equipment, ensuring stable operation and preventing disruptions.

VI. Conclusion

In summary, PTC thermistors play a vital role across various industries. Their characteristics and advantages make them an indispensable part of electronic components. As technology advances, the applications and future prospects for PTC thermistors will continue to expand.