In today's rapidly evolving era of technological advancement, gas sensors have emerged as critical detection tools widely utilized across various fields, particularly holding significant importance within the electronic components industry. With heightened environmental awareness and the push towards industrial automation, the demand for gas sensors continues to escalate, serving as a key driver of industry innovation. This article explores the concepts, classifications, working principles, characteristics, advantages, and applications of gas sensors.

Catalog

IV. Characteristics & Advantages

I. What are Gas Sensors?

Gas sensors are devices designed to detect various gas components and concentrations in the air. These sensors operate by altering the resistance of internal materials based on the concentration of the detected gas, thereby producing a corresponding potential difference measurable as output voltage. This voltage value helps determine the type and concentration of the gas.

II. Types of Gas Sensors

Gas sensors encompass a diverse range depending on their internal sensing materials:

· Semiconductor / Metal Oxide-based Gas Sensors: These sensors feature a sensing element composed of metal oxides like tin dioxide (SnO2), integrated onto a substrate with electrodes and a heater. Gas molecules adhering to the metal oxide surface modify the sensor's electrical conductivity, thereby altering its resistance. They are highly sensitive to a broad spectrum of gases and are relatively cost-effective. However, they are susceptible to environmental factors such as temperature and humidity, necessitating regular calibration that can impact their longevity.

· Electrochemical Gas Sensors: Utilizing electrodes immersed in an electrolyte, electrochemical sensors generate electrical signals through gas-induced electrochemical reactions. They typically consist of working, counter, and reference electrodes enclosed in a compact casing with a gas-permeable membrane. These sensors are renowned for their precision and low power requirements but may be susceptible to gas poisoning and have a limited operational lifespan due to the consumption of active materials.

· Non-Dispersive Infrared (NDIR) Gas Sensors: NDIR sensors utilize an infrared light source, a gas sample chamber, a wavelength filter, and an infrared detector to detect gas presence and concentration. Specific gases absorb distinct infrared wavelengths, with the detector quantifying the absorbed light to determine gas concentration. NDIR sensors are highly accurate, durable, and resistant to sensor contamination. However, they are more costly and are restricted to gases that absorb infrared light.

· Catalytic Gas Sensors: These sensors employ a catalyst-coated element (often platinum) within a Wheatstone bridge circuit. When combustible gases oxidize on the catalyst surface, heat is generated, resulting in a change in resistance that is measured by the circuit. Catalytic sensors excel in detecting low gas concentrations with rapid response times but require oxygen for operation and may be susceptible to chemical interference.

III. Working Principles

Gas sensors operate on distinct principles:

· Semiconductor Gas Sensors: Alter conductivity in response to gas exposure, detected through electrical circuits to identify gas type and concentration.

· Electrochemical Gas Sensors: Facilitate gas oxidation-reduction reactions at electrode surfaces, generating currents proportionate to gas concentrations.

· Infrared Gas Sensors: Measure gas concentrations by assessing infrared light absorption properties specific to gas types.

IV. Characteristics & Advantages

Gas sensors exhibit key features beneficial for various applications:

· High Sensitivity and Precision: Capable of detecting extremely low gas concentrations with high accuracy, suitable for precise measurement requirements.

· Fast Response Time: Rapidly responds to gas fluctuations, ideal for environments necessitating real-time monitoring.

· Stability and Reliability: Incorporate advanced materials and processes to ensure prolonged operation in harsh environmental conditions.

V. How to Use Gas Sensors?

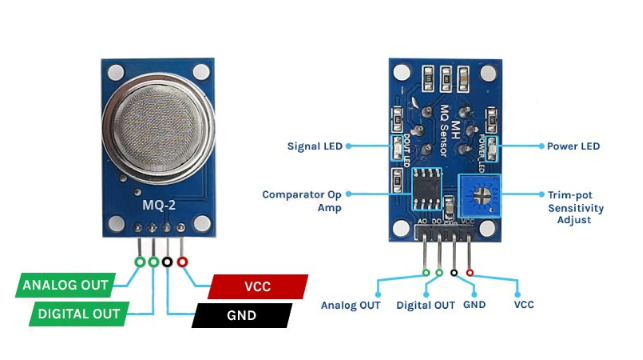

Basic gas sensors typically feature six terminals, with four serving as input or output (A, A, B, B) and the remaining two (H, H) designated for heating the sensor coil. These sensors are commonly available as modules, comprising the sensor itself and a comparator IC. The module includes:

· Vcc: Power supply

· GND: Ground connection

· Digital Output: Provides logical high or low output indicating the presence of toxic or combustible gases.

· Analog Output: Produces a continuous voltage output proportional to gas concentration, requiring external circuitry for digital signal processing.

As discussed earlier the output of a gas sensor alone will be very small (in mV) so an external circuit has to be used in order to get a digital high-low output from the sensor.

VI. Applications

Gas sensors find widespread application across diverse sectors:

· Industrial Production: Monitor hazardous gas leaks during manufacturing processes, ensuring workplace safety in industries such as petrochemicals and steel production.

· Environmental Monitoring: Detect air pollutants like CO2, CO, and H2S to support environmental protection initiatives and safeguard public health.

· Healthcare: Used in respiratory monitoring, anesthesia gas monitoring, and metabolic diagnostics, providing critical health data through accurate gas analysis.

· Safety Monitoring: Deployed in mines, tunnels, and hazardous environments to detect combustible and toxic gases, preventing accidents and ensuring personnel safety.

· Smart Homes: Integrated into household systems to monitor indoor air quality, detecting harmful gases like formaldehyde and CO2, thereby enhancing living standards.

VII. Conclusion

The future outlook for gas sensors within the electronic components industry is promising. With ongoing technological advancements and increasing market demand, gas sensors are poised to play an increasingly pivotal role. Whether in industrial production, environmental protection, healthcare, safety monitoring, or smart homes, gas sensors continue to enhance convenience and safety across various aspects of our lives and work.