NVIDIA's latest AI processor, Blackwell, is experiencing unprecedented demand, prompting CEO Jensen Huang to suggest the possibility of adding new manufacturing partners if needed. This has led to interest from Samsung Electronics. However, South Korean media have criticized Samsung's wafer manufacturing quality, noting that its yield rates fall short compared to Taiwan Semiconductor Manufacturing Company (TSMC), making it premature to expect Samsung to secure NVIDIA's manufacturing orders.

According to The Korea Times, Huang expressed his deep appreciation for TSMC's efforts to meet the high demand for Blackwell at a Goldman Sachs seminar last week. He indicated that while NVIDIA might consider other manufacturing partners to ramp up production, there could be risks to product quality, implicitly pointing to concerns about Samsung's manufacturing standards.

Despite being the world's second-largest wafer foundry, Samsung has struggled with yield rates in advanced processes. In the first quarter of this year, Samsung's 3nm process had yield rates in the single-digit percentages, causing delays in shipping samples of its Exynos 2500 chipsets. Although yield rates improved to 20% in the second quarter, this still fell short of the 60% threshold required for mass production, leading Samsung to delay its expansion plans for the P4 wafer fabrication plant in Pyeongtaek.

The P4 plant, Samsung's newest facility, was initially set to prioritize NAND Flash production, followed by wafer fabrication and DRAM production. However, recent reports suggest that Samsung is reconsidering its strategy, with plans to focus P4 on NAND Flash and High Bandwidth Memory (HBM) production due to the low yield rates in wafer fabrication.

Similarly, Samsung's wafer plant in Taylor, Texas, is facing challenges. Business Korea reports that Samsung has decided to scale back operations and reduce staff at the Texas facility due to low yield rates in its 2nm process. Originally, the Texas plant was a strategic investment to capture U.S. wafer orders, but delays in improving the 2nm process have pushed mass production timelines from the end of this year to 2026.

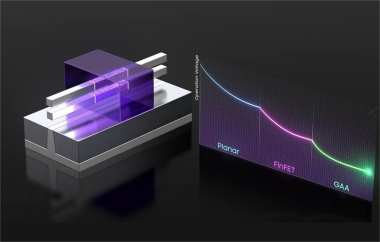

Currently, Samsung's yield rates for processes below 3nm are under 50%, while TSMC's yield rates are between 60% and 70%. This disparity has significantly impacted market share, with TSMC holding a 62.3% share of the global wafer foundry market in the second quarter of this year, compared to Samsung's 11.5%.

An industry expert from South Korea commented, "Samsung's GAA process yield is around 10% to 20%, still below the threshold required for securing orders and mass production."