If you're interested in converting an ATX power supply to a modular power supply or making a DIY heat transfer PCB without transfer paper, you might want to check out this article.

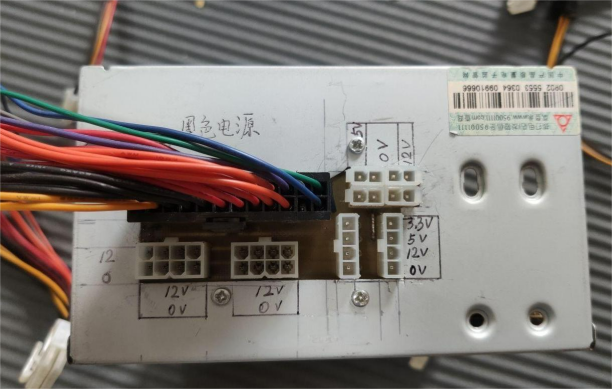

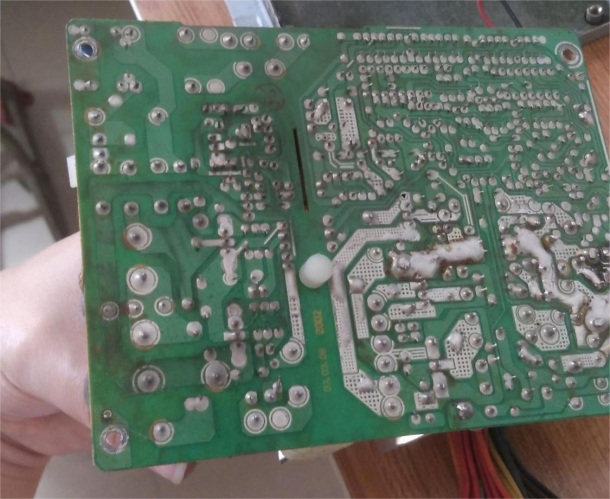

If you have a 350W BUBALUS from Big Bull or an Antec power supply, you can follow this guide to modify it into a modular one.

The key difference in modular power supply structures lies in the cable connectors. If you have a PCB, you can pair it with a few connectors to assemble one.

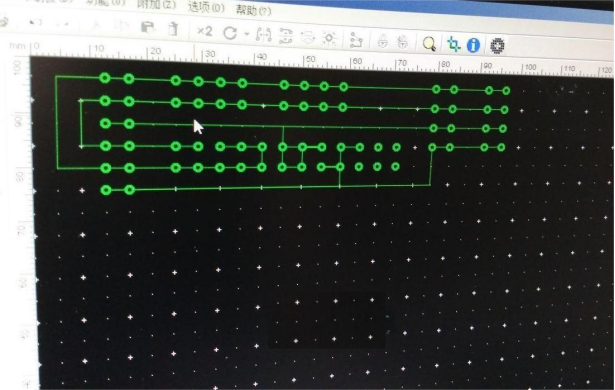

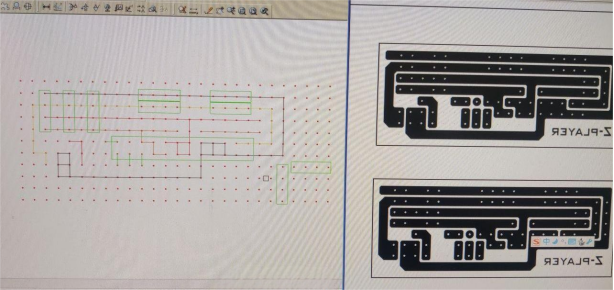

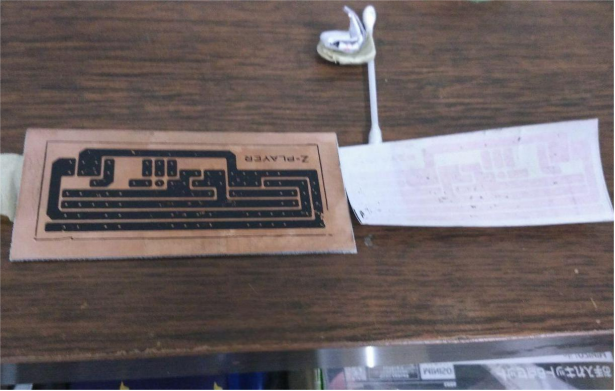

First, you'll need to design the PCB. A simple layout should include a 24-pin connector, CPU, GPU, hard drive, and fan expansion, providing a fairly complete set of interfaces.

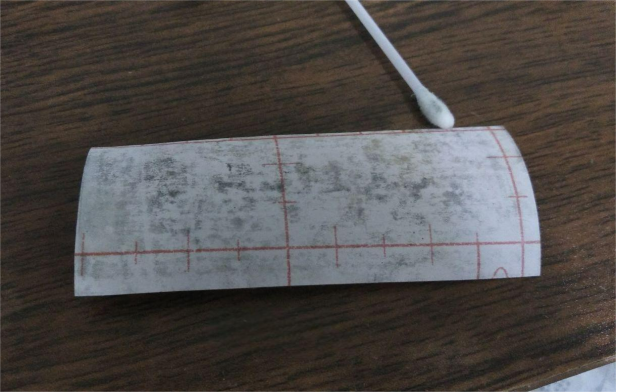

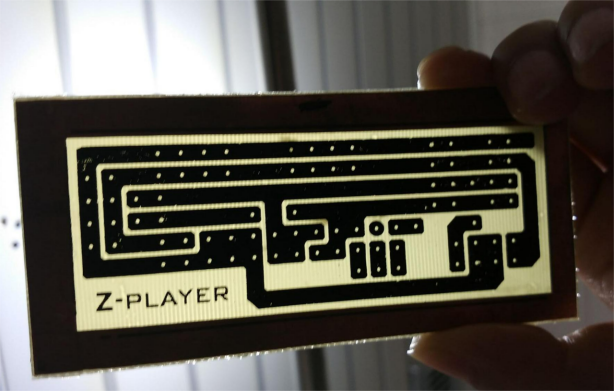

If you've run out of transfer paper and don't want to wait 4 or 5 days for a new batch, you’ll need to find an alternative method. The principle behind transfer paper is that its smooth surface prevents the ink from soaking in at high temperatures. When placed on the PCB, the ink separates from the paper and transfers to the PCB.

Common smooth-surfaced papers like label stickers can work for this. There are various types of these stickers, and you can use the backing paper from self-adhesive stickers made with a laser engraver.

If you don't have a heat transfer machine, you can use an electric hotpot and a CPU heatsink to create a heating unit. Since you'll need to press it by hand, it's a good idea to use some cardboard for insulation. Be sure to clean the surface of the sticker thoroughly, as the plastic film is prone to dust, which could affect ink adhesion.

The result is generally acceptable, and it works for the most part.

Etching took a little time, but the overall result is pretty good. Since the design has relatively thick lines, there's no need for intricate details, but some jumper wires might still be necessary.

The interfaces are only sufficient for current platforms. If you plan to upgrade the system later, you'll need to redesign the adapter board.

That's all.