If you're interested in DIY PC cases, you might want to check out this article.

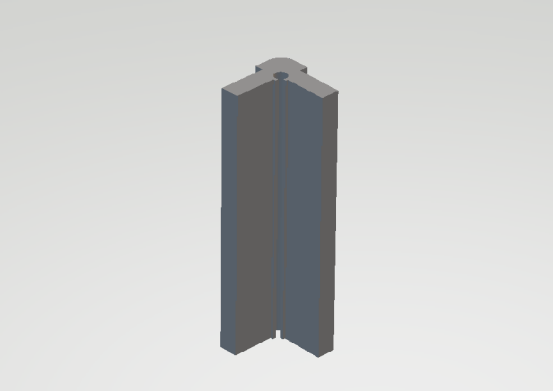

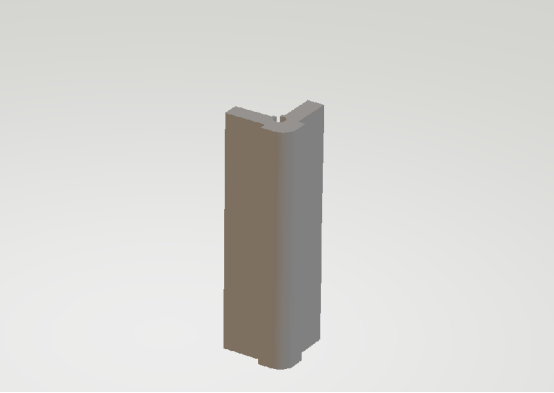

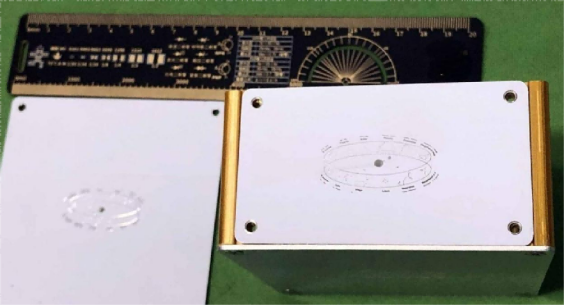

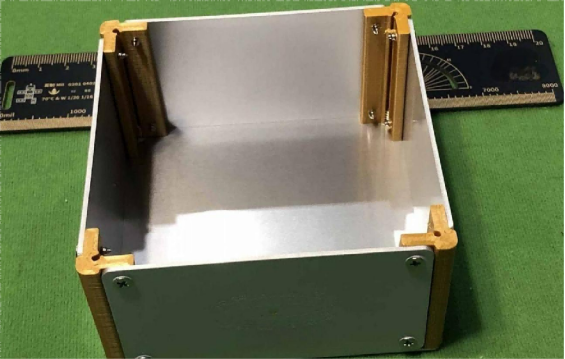

You can try making a small case using an aluminum substrate. You'll need four corner pieces, as shown in the picture, along with one top panel, one bottom panel, two side panels, one back cover, and one front panel.

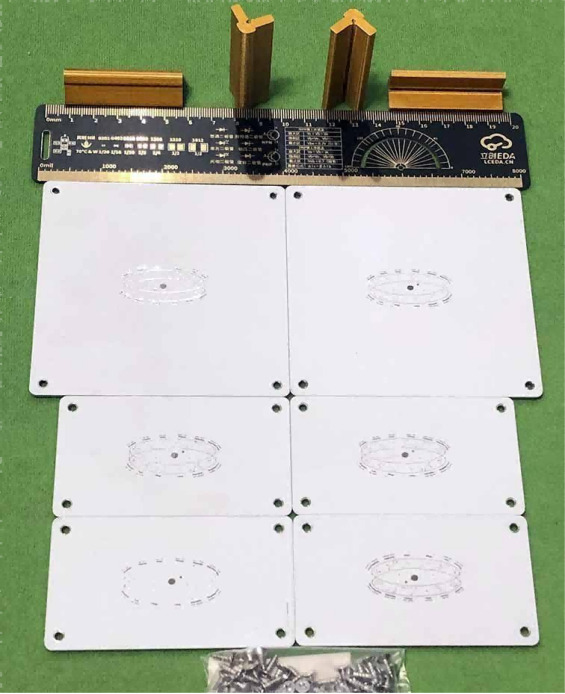

Use eight M3x10 self-tapping screws for the top and bottom, and sixteen M3x5 self-tapping screws for the side panels. If you think the M3x10 screws are too long, you can just use M3x5 self-tapping screws.

The actual materials you'll need are shown in the picture below.

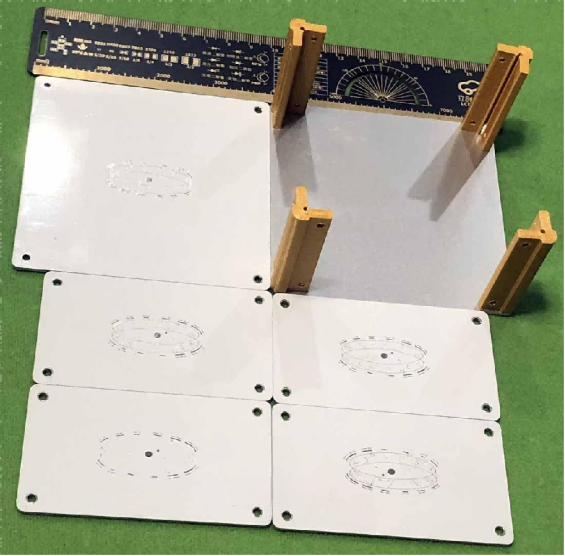

You should start by screwing in the bottom panel first. If you want the bottom to sit flat, you can countersink the holes slightly.

When you install the side panels, it's best to drill 2.5mm pilot holes first—especially if you're using PLA. Without pilot holes, the panels will crack. Just align and drill straight through.

Next, you can get ready to attach the top panel.

There might be small gaps at the rounded corners of the side panels. If that bothers you, you can design the side panels with right angles instead.

Attached are the aluminum substrate layout files for your reference.

Aluminum substrate thickness: 1.6mm, 4 pieces in “PCB_FACE.zip”

Aluminum substrate thickness: 1.6mm, 2 pieces in “PCB_TOP.zip”

Done.