If you're interested in a DIY battery test rig, you might want to check out this article.

If you use batteries frequently, like 10Ah lithium iron phosphate batteries, and need to measure their voltage, you might choose an LQ1060S internal resistance tester or a 150W four-wire discharge tester with 5A charge + discharge. You can also follow this guide to DIY a battery test rig yourself—it might even perform better than the reinforced test probes that come with an internal resistance tester.

But I hadn't bought a battery rack because they seemed too expensive. The ordinary battery racks that most people wouldn't look twice at cost over 30 RMB, which didn't feel worth it. So I decided to make one myself and carry forward the DIY spirit. The best part is the joy you get after building it.

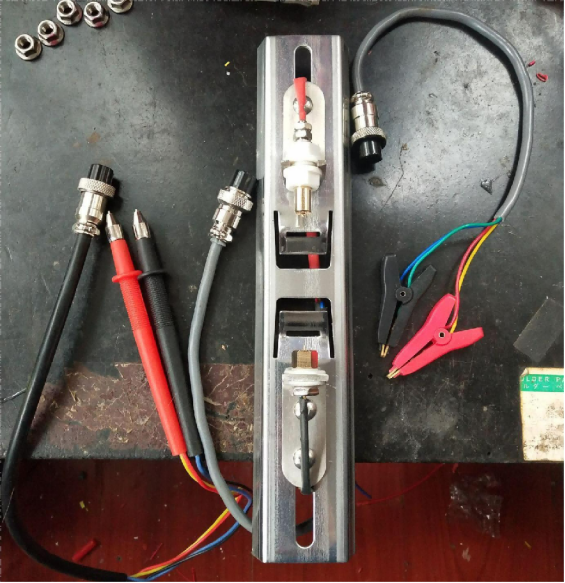

To make this battery rig, you'll need 12mm aviation connectors, 304 stainless steel crossbars, and a pair of gold-plated battery spring pins. You can reuse old wires. Below is the process of making the battery rig.

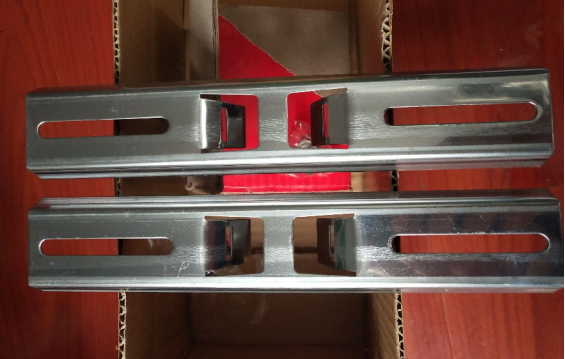

The frame and cable ties look like this:

Angle brackets, frame, and battery spring pins look like this:

The angle brackets are 90° 50x50x3mm, standard 304 stainless steel.

You need to be careful—the edges of the frame are very sharp, so you'll need to use a milling cutter to remove the burrs along the edges.

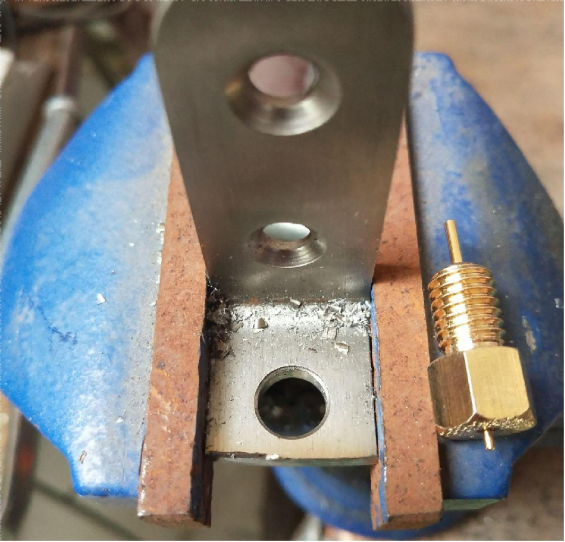

You can use a vise to hold the angle grinder while cutting.

You can cut a 12mm notch first, then attach the negative spring pin.

The positive side requires 8mm. If your angle bracket is 6mm thick, you can widen it with a drill.

The screws that come with the frame can secure the angle brackets, as shown below:

The minimum distance for placing the batteries is 50mm, as shown below:

The maximum distance is 13mm, which is enough. Except for AAA batteries, which don't fit—but that's fine, since rechargeable AAA batteries aren't needed. Of course, you can modify it a little if you want.

Next, you can bend the lower part of the frame upwards to fix the vertical position of the batteries, as shown below:

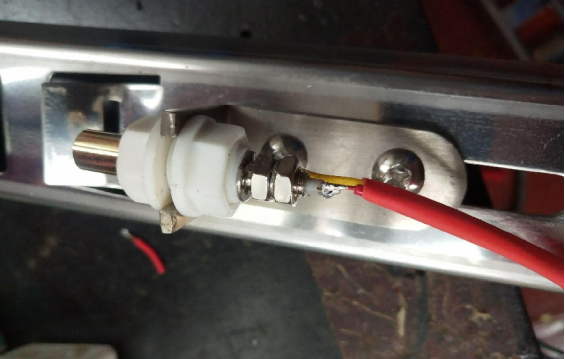

Then, you'll need 12mm aviation connectors. Make sure to get the GX16 model when buying—don't get it wrong.

Next, solder the positive terminal.

Then you can secure it with heat shrink tubing.

Next, connect the negative terminal.

After finishing, the side view looks like this. Be careful not to mix up the positive and negative terminals. In the photo, the positive and negative are reversed, but you can fix it when DIY-ing. Short pin is positive, long pin is negative. Even though the photo shows them reversed, it doesn't affect the measurement. Also, the short pin works better for positive because the short pin is larger, and the exposed metal on the battery casing tends to contact the negative side more.

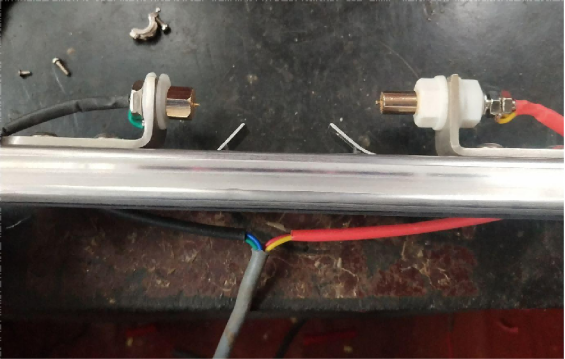

Top-down view looks like this:

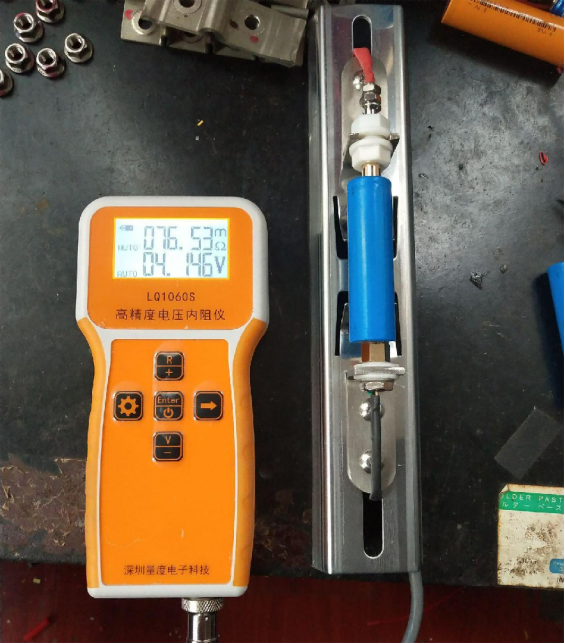

Then you can start testing. The image below shows testing a 18650 battery.

The next image shows testing another 18650 battery:

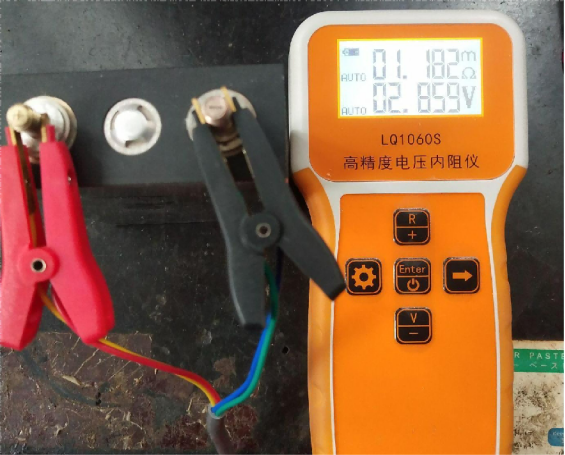

This four-wire Kelvin clip is better than the probes that come with an internal resistance tester. First, it's stable—you clip it on and it immediately shows a reading. Second, the measured internal resistance is lower than with the standard probe.

For the same battery, using the probe gives a higher internal resistance and is very unstable—the value keeps fluctuating and is hard to stabilize. Multiple measurements of internal resistance are inconsistent.

All the components look like this:

End.