In the electronics component industry, resistive touch sensors are a common and classic touch technology. This article will delve into the definition, working principle, characteristics and advantages, applications, and comparison with capacitive touch sensors.

Catalog

I. What are Resistive Touch Sensors?

III. Characteristics and Advantages

V. Capacitive vs Resistive touch sensor

I. What are Resistive Touch Sensors?

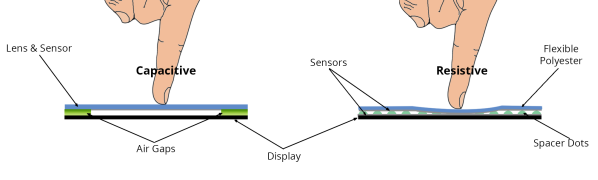

A resistive touch sensor is a type of touch sensor that functions based on changes in electrical resistance. It detects touch positions by utilizing the variation in resistance between two conductive layers. Its basic structure consists of two layers of materials: a flexible top layer and a rigid bottom layer. Both layers are coated with a conductive material, typically indium tin oxide (ITO), and separated by small insulating spacers.

· Flexible Top Layer: The top layer is typically made of a flexible material like polyester or polyethylene. It deforms when pressure is applied, forming a circuit with the bottom layer upon contact. This transparent layer is coated with a thin, conductive material.

· Rigid Bottom Layer: The bottom layer is usually composed of glass or a similar rigid material. Like the top layer, it's coated with a conductive material.

When a user touches the screen, the top layer deforms and establishes contact with the bottom layer, altering the resistance between the two layers. This change in resistance allows the sensor to detect the touch position. Resistive touch sensors are widely used in various devices such as smartphones, ATMs, kiosks, and medical equipment.

II. Working Principle

The operation of resistive touch sensors relies on the principle of electrical resistance. Pressure on the sensor's surface causes a change in resistance, which is then translated into a specific input. When a user touches the screen, the contact area between the two conductive layers increases, reducing the resistance. The sensor measures this resistance change and converts it into corresponding coordinates to determine the touch position.

This type of sensor is particularly effective because it can detect touch from almost any kind of object – be it a stylus, a gloved hand, or a bare finger.

III. Characteristics and Advantages

· Cost-effective: Manufacture of resistive touch sensors is relatively inexpensive compared to other touch technologies, making them suitable for mass production.

· Easy to manufacture: The simple structure of resistive touch sensors facilitates easy manufacturing and maintenance.

· Durable: With no mechanical moving parts, resistive touch sensors exhibit high durability.

· High precision: Resistive touch sensors offer high precision, performing excellently in various applications.

IV. Applications

Resistive touch sensors find extensive applications in various fields, including:

· Smartphones and Tablets: Early smartphones and tablets commonly utilized resistive touch screen technology.

· Industrial Control Panels: Due to their durability and reliability, resistive touch sensors are frequently used in industrial control panels. These panels often feature resistive touch screens with properties like waterproofing, dust resistance, and high-temperature resistance.

· Medical Equipment: In medical devices, resistive touch sensors are used for monitoring and operating panels. These sensors must meet high precision and reliability standards, as well as comply with medical industry safety regulations.

V. Capacitive vs Resistive touch sensor

A Capacitive touch sensor is an electronic device that senses the change in capacitance when a finger or a stylus is touching it.

Capacitive touch sensors measure the change in capacitance between two electrical plates. This happens when a human finger or a conductive stylus applies pressure to the touchscreen’s surface.

While resistive touch sensors offer certain advantages, they also have limitations compared to capacitive touch sensors. Capacitive touch sensors provide higher sensitivity and response speed, support multi-touch, and can detect finger positions without direct screen contact. Therefore, capacitive touch sensors may be more suitable for some applications.

VI. Conclusion

Resistive touch sensors remain a crucial touch technology in the electronics component industry, thanks to their simple construction, stability, and widespread application.