Cable connectors are indispensable components in modern electronic devices, playing a critical role in power transmission, signal transmission, and even data connections. From household appliances to complex industrial control systems, the design and selection of cable connectors directly influence the stability, reliability, and performance of electronic products. This article will explore the definition, working principle, types, characteristics and advantages, applications, and selection tips for cable connectors.

Catalog

III. Types of Cable Connectors

IV. Characteristics and Advantages

I. What are Cable Connectors?

A cable connector is a device used to connect cables with other electronic components, enabling the fast and secure transmission of electrical current, voltage, or signals. Cable connectors typically consist of metal contacts, housings, and spring mechanisms, ensuring a reliable connection between cables while offering the flexibility to disconnect and reconnect when needed. This makes them highly flexible and maintainable.

II. Working Principle

The working principle of a cable connector is based on a plug-and-play connection. When the connector's plug is mated with the socket, electrical contact is formed between the contacts, ensuring stable transmission of power or signals. The metal contacts of the connector are pressed by a spring mechanism to ensure adequate contact pressure, reducing contact resistance and improving connection quality. To enhance reliability, the connector housing is typically designed to be waterproof, dustproof, and vibration-resistant, meeting the demands of harsh environments.

III. Types of Cable Connectors

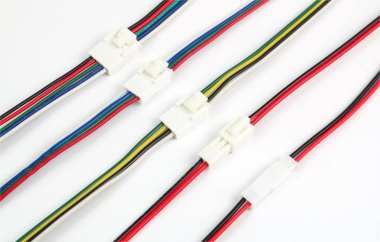

· Wire-to-Wire: One end is soldered or crimped to the cable, while the other end connects to another cable through plug-and-play. Common in household power cords and extension cables.

· Wire-to-Board: One end connects to a cable, while the other end plugs into a PCB header. Widely used for internal power and signal wiring.

· Panel-Mount: Fixed to the equipment panel or chassis, providing an external cable connection interface, such as IEC 60320 power connectors and RJ45 network interfaces.

· Hybrid: Integrates power, signal, fiber optic, or pneumatic contacts in a single housing, enabling modular and quick replacements.

· Circular & Specialty: High-reliability circular connectors like M12 and MIL-DTL-38999, designed for harsh environments and military/aerospace applications.

IV. Characteristics and Advantages

· Maintainability and Upgradability: The plug-and-play design simplifies product maintenance and functional upgrades, reducing downtime.

· High Reliability: Premium materials and precision spring contacts ensure low contact resistance and vibration resistance.

· Strong Compatibility: A wide range of standardized specifications (e.g., USB, HDMI, Ethernet) meets diverse application needs.

V. Applications

· Consumer Electronics: USB-C, HDMI, and DisplayPort interfaces for devices like smartphones, tablets, and set-top boxes.

· Communication Networks: Fiber optic (LC/SC) and Ethernet (RJ45) connectors for data centers and base stations.

· Automotive Electronics: Waterproof circular connectors for power battery management systems and in-vehicle infotainment systems.

· Industrial Automation: Interfaces for sensors, actuators, and fieldbus systems (M8/M12).

· Aerospace and Defense: High-end military-standard connectors like MIL-DTL-38999 and ARINC.

VI. Selection Tips

· Conductor Material: Brass spring contacts offer excellent conductivity and mechanical strength. Gold/nickel plating enhances oxidation resistance and contact stability, making them suitable for high-frequency signals and long-life plug-and-play scenarios.

· Insulation and Housing Materials: Plastic housings are lightweight, cost-effective, and offer excellent insulation properties. Common engineering plastics like PBT and PA66 are used, though they may deform in high-temperature environments. A metal-reinforced skeleton can be added in critical areas.

When selecting cable connectors, besides considering materials and structure, pay attention to the following:

· Protection Level: Choose the appropriate sealing rating (e.g., IP65, IP67) based on the operating environment to ensure the device functions well under harsh conditions.

· Electrical Performance: Select connectors that meet the voltage, current, and signal frequency requirements of the device to avoid signal loss or poor contact issues.

· Ease of Installation and Maintenance: Choose connectors that are easy to plug and unplug, facilitating future maintenance and upgrades.

· Durability: Choose materials with high durability to ensure long-term, stable operation of the connectors.

VII. Conclusion

As essential components in electronic devices, cable connectors play a critical role in the stability and performance of systems. Whether in consumer electronics, communications, automotive, industrial, or medical fields, selecting the right connectors and materials ensures the efficiency and reliability of the product. With technological advancements, cable connectors will continue to evolve, developing more functions to meet the ever-changing demands of the industry.