Have you ever wondered why today's electronic devices are becoming slimmer and more compact, yet their functionality keeps growing? Inside smartphones, laptops, and high-definition TVs, there's one crucial component that often goes unnoticed—the FFC cable. This thin, flexible connector is the unsung hero behind high-density integration in modern electronics.

Catalog

II. How FFC Cables Make Production Easier

IV. The 5 Key Advantages of FFC Cables

I. What is an FFC Cable?

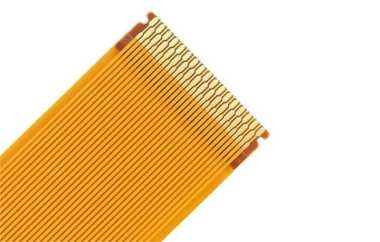

FFC stands for Flexible Flat Cable. It's a type of cable made with flat, flexible conductors (usually tinned copper wires) bonded between ultra-thin flexible insulating films at high temperature. The main difference between FFC and FPC (Flexible Printed Circuit) lies in the manufacturing process: FPC uses chemical etching to create circuits on a flexible copper-clad substrate, while FFC sandwiches flat copper foil between two layers of insulating film. This basic structural difference gives FFC an advantage in production cost and manufacturing efficiency, making it a preferred choice for many electronic products.

Standard FFC cables come in a variety of pitches—0.5mm, 0.8mm, 1.0mm, 1.25mm, 1.27mm, 1.5mm, 2.0mm, 2.54mm, and more—to meet different electronic device connectivity requirements.

II. How FFC Cables Make Production Easier

In modern electronics manufacturing, FFC cables significantly simplify the production process. By standardizing and streamlining wiring, they greatly improve assembly efficiency. Manufacturers no longer need to spend time organizing complex wire harnesses; they can simply select the right FFC cable and quickly complete the installation.

The structure of FFC cables also makes them ideal for automated production, dramatically reducing the human labor needed for traditional wiring assembly. This convenience translates directly into cost savings, allowing companies to maintain high quality while controlling production costs and boosting market competitiveness.

III. FFC Cable Standards

FFC cables follow a comprehensive set of technical standards to ensure compatibility and reliability across applications.

· Pitch: The distance between the centers of two conductors, commonly 0.3mm, 0.5mm, 0.8mm, 1.0mm, 1.25mm, 1.27mm, 2.0mm, or 2.54mm.

· Number of Pins (Conductors): The number of copper conductors in the cable, typically ranging from 20 to 100 or more.

· Conductor Size: Common dimensions include 0.035mm × 0.3mm, 0.05mm × 0.5mm, 0.05mm × 0.7mm, 0.05mm × 1.0mm, 0.1mm × 0.5mm, 0.1mm × 0.7mm, 0.1mm × 0.8mm, and 0.1mm × 1.6mm.

· Exposure Length: The length of exposed conductor at both cable ends, usually 3–5mm for connector contact, extendable to 3–10mm in some cases.

· Stiffener: A critical component that adds rigidity to the cable ends, making insertion or removal from connectors easier and more reliable. Stiffeners usually range from 3.5–20mm in length.

Depending on stiffener placement and connection type, FFC cables come in various models:

· Type A: Stiffeners at both ends glued to the insulating film

· Type B: Stiffeners cross-glued directly to the insulating film

· Type C: Stiffeners at both ends glued directly to the conductors

These standardized designs ensure FFC cables perform reliably across diverse applications.

IV. The 5 Key Advantages of FFC Cables

1. High-Density Integration and Space Savings

One of the most significant advantages of FFC cables is their ability to integrate densely, saving valuable space. The flat design reduces the volume of electronic products, helping manufacturers improve efficiency and cut costs. FFC cables weigh and occupy 70% less space than traditional round wire harnesses. This space-saving feature allows designers to implement more complex functions in limited areas, crucial for today's compact portable devices.

2. Exceptional Flexibility and Durability

FFC cables are highly flexible—they can bend, twist, and fold, enduring millions of cycles without damage. This makes them ideal for internal connections in systems requiring continuous or periodic motion. Unlike rigid PCB solder points that may fail after hundreds of cycles due to mechanical stress, FFC cables can withstand millions of dynamic bends, extending the product's operational life.

3. Simplified Assembly and Improved Reliability

By simplifying wiring, FFC cables make connections more straightforward. Reducing the need for traditional internal components—solder points, jumper wires, and wire harnesses—enhances assembly reliability and product quality. In traditional systems, complex internal wiring often leads to higher component misalignment. FFC cables, designed for single-method assembly, eliminate many human errors, boosting consistency and reliability.

4. Excellent Electrical Performance and Heat Resistance

FFC cables provide superior electrical characteristics, such as low dielectric constant for fast signal transmission. They also offer excellent thermal performance, allowing components to cool effectively and operate normally at higher temperatures. Many FFC cables use flame-retardant polyester films as insulation, with a temperature range of -40°C to +105°C, and some models can even withstand higher operating temperatures. This broad thermal range allows them to handle demanding environments.

5. Application Flexibility and Versatility

FFC cables can adapt to different shapes and special package sizes, limited only by space constraints. They can handle bending, twisting, or unusual layouts, making them suitable for nearly any electronic device that requires flexible connectivity. This versatility makes FFC cables the first choice for designers solving complex connection challenges.

V. Applications of FFC Cables

FFC cables are widely used for connections between printer heads and motherboards, plotters, scanners, copiers, audio equipment, LCD appliances, fax machines, and various disc players. They are ubiquitous in modern electronic devices.

Common models:

· Type A: Both ends connected, stiffeners on the insulating film

· Type B: Stiffeners cross-glued on the insulating film

· Type C: Stiffeners glued directly to conductors at both ends

· Type D: Stiffeners cross-glued on conductors at both ends

· Type E: One end with stiffener on insulating film, other end soldered

· Type F: Both ends with stiffeners on insulating film, half internally stripped

· Type G: Both ends directly soldered

VI. Conclusion

As technology continues to advance, FFC cables are becoming increasingly essential in the electronics industry. Their compact size, lightweight, and high reliability make them ideal for IoT devices, wearable electronics, automotive systems, and industrial automation.

While there are some limitations—such as potentially higher costs in specific applications and the need for professional knowledge for installation and maintenance—the overall advantages of FFC cables make them an irreplaceable connection solution in modern electronics.