If you often work with SMD LEDs and have a lot of them to handle, you can follow this guide to DIY a PTC heating station. If you're interested, go ahead and keep reading.

First, you need to learn a bit about soldering SMD components. You can prepare a 400W PTC—one without temperature control is fine too.

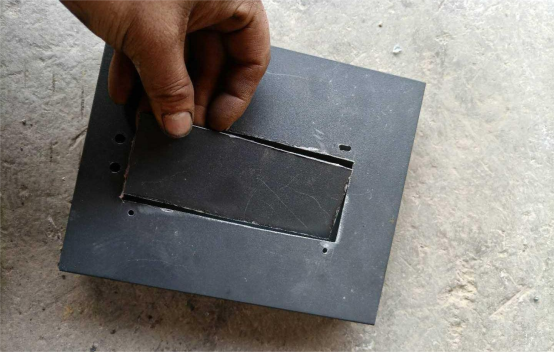

Next, you'll need an iron box, like the kind from a Netcore router.

After comparing the sizes, you can start cutting it open.

You can choose to use an angle grinder for the cutting.

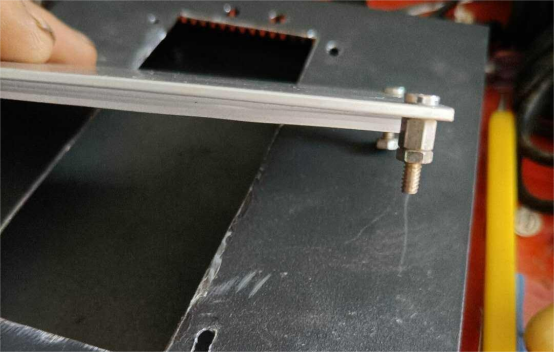

Then you need to mark and drill the holes for positioning, and prepare some screws for assembly.

You should use copper standoffs for isolation, which will prevent the iron casing from wasting heat.

Once assembled, it will look like the picture above, before wiring.

You can also choose taller copper standoffs, like the style shown in the picture above.

If you want to replace them, you'll need to enlarge the holes and change them to countersunk screw threads.

Once everything is installed, you can start testing.

After heating, you can successfully remove the SMD LEDs.

Additionally, you can set up the socket in the bottom box. You can make it a large IEC plug or a figure-8 plug, and you can even add a switch with an indicator light, as shown in the picture below.

This makes removing LEDs really easy, heats up quickly, and runs around 400W–220V.

Done.