NTC thermistors, or Negative Temperature Coefficient thermistors, are commonly used temperature sensors and resistive components in the global electronics industry. They are known for their ability to change resistance in response to temperature fluctuations and are widely used in various electronic devices. This article provides an in-depth overview of NTC thermistors, covering their definition, operating principles, types, characteristics and advantages, and applications.

Catalog

III. Characteristics and Advantages

V. NTC Thermistors vs. PTC Thermistors

I. What are NTC Thermistors?

NTC thermistors, or Negative Temperature Coefficient thermistors, are devices whose resistance changes in response to temperature changes. When the temperature increases, the resistance of an NTC thermistor decreases. They are primarily used as resistive temperature sensors and current-limiting devices. The temperature sensitivity of NTC thermistors is about five times greater than that of silicon temperature sensors (silistors) and about ten times greater than that of resistance temperature detectors (RTDs). NTC thermistors typically operate within a range from −55 to +200 °C.

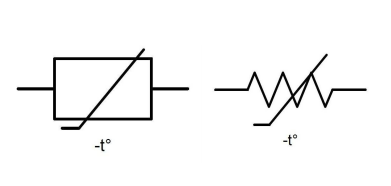

△ The symbol of NTC Thermistor

II. Principles of Operation

The operation of NTC thermistors is based on the properties of their materials. These devices are usually made from semiconductor materials, such as metal oxides. When the temperature rises, these materials release charge carriers, resulting in a decrease in resistance. By measuring changes in resistance, NTC thermistors can accurately detect and respond to temperature fluctuations.

III. Characteristics and Advantages

· High Sensitivity: NTC thermistors respond quickly to temperature changes, providing prompt detection and feedback. This makes them highly effective in temperature monitoring and control systems.

· Low Cost: Compared to other types of temperature sensors, NTC thermistors are relatively inexpensive to manufacture. They are typically made from simple materials, such as semiconductor ceramics and metal oxides, which are cost-effective and easy to produce.

· Small Size: NTC thermistors are compact, allowing them to be easily integrated into various circuits and devices. This makes them practical for use in limited space applications.

· High Reliability: NTC thermistors demonstrate stable and reliable performance under different operating conditions. They can operate across a wide temperature range and have a long lifespan.

· Wide Measurement Range: NTC thermistors offer a broad measurement range, from low to high temperatures, making them suitable for various applications.

IV. Applications

NTC thermistors have a wide range of applications across multiple industries. Here are some key areas where they are used:

· Consumer Electronics: In devices such as smartphones and laptops, NTC thermistors monitor battery and processor temperatures to prevent overheating and ensure proper device operation.

· Household Appliances: NTC thermistors are used in refrigerators, air conditioners, and washing machines to monitor and control temperatures, ensuring efficient performance and extended lifespan.

· Automotive: NTC thermistors are used to monitor critical components such as engine and radiator temperatures, ensuring the stable operation of vehicles. They are also used to monitor battery temperatures, ensuring the safety of electric vehicles.

· Medical Equipment: NTC thermistors are used to monitor patient body temperatures and other physiological parameters, ensuring the accuracy and reliability of medical devices.

· Industrial Control: In industrial production, NTC thermistors are used for temperature control, equipment overheat protection, and fire alarm systems, ensuring the safety and efficiency of production processes.

V. NTC Thermistors vs. PTC Thermistors

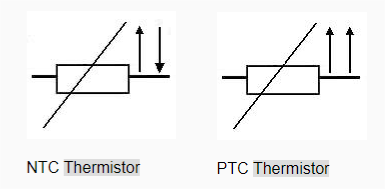

NTC thermistors and PTC thermistors have distinct differences in how they respond to temperature changes:

· NTC Thermistors: As the temperature increases, the resistance of NTC thermistors decreases. This characteristic makes them suitable for temperature monitoring and control circuits.

· PTC Thermistors: As the temperature increases, the resistance of PTC thermistors rapidly increases. This characteristic makes them suitable for overcurrent protection and thermal fuse applications.

VI. Conclusion

In summary, NTC thermistors play a crucial role in the electronics industry. Due to their high sensitivity, low cost, compact size, and reliability, they are widely used across various fields. As technology continues to advance, the performance of NTC thermistors will further improve to meet the diverse needs of the market.