In the electronics industry, ballast resistors may not be the flashiest components, but they are essential for many lighting and gas discharge devices. From traditional fluorescent lamps to modern LED drivers, ballast resistors quietly play a critical role in stabilizing current and ensuring devices start and run properly. This article provides a detailed look at their definition, types, working principles, characteristics and advantages, and the difference between ballasts and starters.

Catalog

I. What Are Ballast Resistors?

II. Types of Ballast Resistors

IV. Characteristics and Advantages

I. What Are Ballast Resistors?

A ballast resistor is an electrical device used to limit current, mainly applied in gas discharge lamps (such as fluorescent lamps, high-pressure sodium lamps, metal halide lamps) and certain types of LED lighting systems. Its core function is to prevent the current from increasing indefinitely, which could damage the equipment, and to ensure that the lamp operates under a safe and stable current. Simply put, without a ballast resistor, many lighting devices either wouldn't start properly or would burn out quickly.

II. Types of Ballast Resistors

Ballast resistors can be classified into two main types based on their working principle and structure:

· Inductive Ballasts (Magnetic Ballasts): These are made of silicon steel sheets and copper wire coils and use the inductive reactance to limit current. They have a simple structure, low cost, and long lifespan and were widely used in early fluorescent lighting. However, due to their low power factor, high energy consumption, bulky size, and flickering issues, they are gradually being replaced by more efficient products.

· Electronic Ballasts: Electronic ballasts use semiconductor circuits to convert mains electricity into high-frequency AC to drive lamps. They offer advantages like high energy efficiency, lightweight design, flicker-free operation, and support for dimming. They also integrate power factor correction (PFC) and protective functions, making them the mainstream choice in the market today.

III. Working Principles

1. Inductive Ballast Working Principle

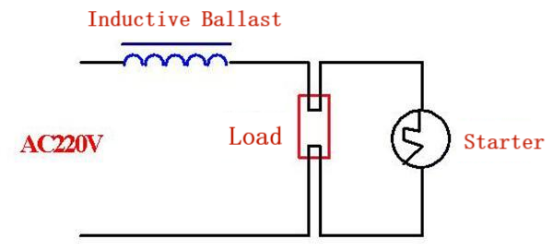

When connected to a 220V AC power supply, the current flows through the ballast, and the lamp filaments and starter begin to heat the filaments. The starter is initially open, but under higher voltage, the gas inside it produces an arc, causing the bimetal strip to bend and the electrodes to touch, forming a path to heat the filaments. The bimetal then cools and the electrodes open. Since the inductive ballast is a reactive load, when the circuit suddenly interrupts, a high-voltage pulse lasting about 1 millisecond and ranging from 600V to 1500V appears across the lamp, igniting it. The exact voltage depends on the lamp type.

Once the lamp is lit, the voltage across it drops quickly. At this point, the ballast limits the current and creates a 55–65° phase difference between the supply voltage and the lamp current, maintaining the secondary starting voltage to ensure stable operation.

Although inductive ballasts are simple and long-lasting, their low power factor, poor starting performance, high energy consumption, bulkiness, and noticeable flicker have led to their gradual replacement by electronic ballasts.

2. Electronic Ballast Working Principle

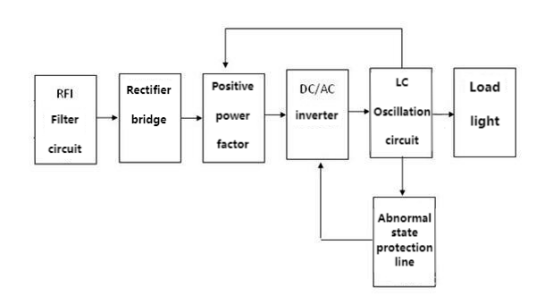

Mains power first passes through an RF interference filter and then through a full-wave rectifier and power factor correction circuit, converting it to DC. This DC is then converted by a DC/AC inverter into a high-frequency AC signal of 20kHz to 100kHz, which is fed into an LC series resonant circuit connected to the lamp. This circuit heats the filaments while generating high voltage across the capacitor, applied to the lamp terminals to transition the lamp from discharge to conduction and finally into stable illumination.

After the lamp is lit, the high-frequency inductance (the inductive component in the electronic ballast) limits the current rise, ensuring the lamp receives the proper voltage and current for normal operation. For enhanced reliability, electronic ballasts usually include protection circuits against abnormal states, voltage and current surges, and temperature fluctuations.

IV. Characteristics and Advantages

· Inductive Ballasts: Robust structure, long lifespan, low cost, good electromagnetic compatibility; however, they are less efficient, bulky, heavy, noisy, and prone to flickering.

· Electronic Ballasts: High energy efficiency, significant energy savings, lightweight, flicker-free, faster and quieter start, dimmable and controllable, with integrated protective functions; however, the circuitry is more complex and relies on high-quality components.

V. Ballasts vs. Starters

Ballasts and starters are two distinct components in gas discharge lamp systems that often work together but have different functions:

· Ballast: Primarily limits and stabilizes the working current after the lamp starts, preventing excessive current and ensuring the lamp operates within rated parameters. It controls the current during normal lamp operation.

· Starter: Produces a brief high-voltage pulse to break down the gas inside the lamp and help it ignite. It mainly operates during the startup phase and stops functioning once the lamp reaches stable illumination.

In short, the starter is responsible for ignition, while the ballast maintains stable operation.

VI. Conclusion

With the rise of IoT and smart lighting, digitally dimmable ballasts and smart ballasts with communication interfaces have become key research focuses. Ballast resistors play a crucial role in the electronics industry. As lighting technology evolves, electronic ballasts, with their high efficiency, low energy consumption, and quiet operation, are gradually replacing traditional inductive ballasts and becoming an indispensable part of modern lighting systems.