Thermistors hold a crucial position in the electronic components industry. As resistors whose resistance changes in response to temperature, thermistors find widespread use in temperature monitoring and control across various fields, including household appliances, medical devices, automotive, and aerospace. This article offers a comprehensive overview of thermistors, exploring their definition, working principle, types, characteristics and advantages, and applications.

Catalog

IV. Characteristics and Advantages

I. What Are Thermistors?

A thermistor is a type of temperature-sensitive resistor whose resistance changes based on temperature. The term is a blend of “thermal” and “resistor.” It is crafted from metallic oxides formed into beads, disks, or cylindrical shapes, and then encapsulated in an impermeable material such as epoxy or glass.

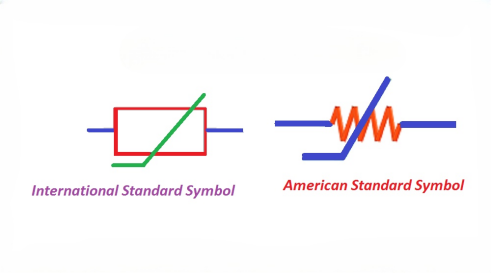

△ Thermistor Symbol

II. Types

Based on their response to temperature changes, thermistors are primarily classified into two types: Negative Temperature Coefficient (NTC) and Positive Temperature Coefficient (PTC) thermistors:

· NTC Thermistors: These are typically composed of metallic oxides and other semiconductor materials. They come in various shapes such as disc, bead, or chip, with multiple encapsulation styles. NTC thermistors are sensitive to temperature changes, with resistance decreasing exponentially as temperature rises.

· PTC Thermistors: Typically made from materials like barium titanate, PTC thermistors experience a sudden increase in resistance at a specific temperature. Common shapes include ring and rectangular forms, widely used for circuit protection.

III. Working Principle

· Negative Temperature Coefficient (NTC) Thermistors: As temperature increases, the resistance of NTC thermistors decreases. This behavior is due to the properties of the semiconductor materials used; an increase in temperature raises the charge carrier concentration, thus lowering resistance.

· Positive Temperature Coefficient (PTC) Thermistors: As temperature rises, PTC thermistors exhibit increased resistance. This is due to phase transition or structural changes in the resistance material, causing a rapid rise in resistance at a particular temperature point.

IV. Characteristics and Advantages

· High Sensitivity: Thermistors respond quickly to temperature changes and offer high sensitivity.

· Compact Size: Thermistors are generally small, making them easy to integrate into circuits.

· Cost-Effective: Thermistors are less expensive to produce compared to other types of temperature sensors.

· Variety of Packaging Options: Thermistors come in various packaging forms, including disc, bead, and surface-mount device (SMD), allowing them to suit different application scenarios.

V. Applications

· Temperature Measurement and Monitoring: NTC thermistors are commonly used for temperature monitoring and control in household appliances, electronic devices, medical instruments, and more.

· Temperature Compensation: In certain circuits, thermistors help offset changes in resistance due to temperature variations.

· Overcurrent Protection: PTC thermistors act as overcurrent protectors in circuits, preventing damage from excessive current.

· Battery Management: Thermistors play a key role in battery management systems, monitoring and regulating battery temperature for safe operation.

· Automotive Electronics: Thermistors are widely used in automotive electronics, such as engine temperature monitoring and car battery temperature management.

VI. Conclusion

Thermistors offer broad application potential in the electronic components industry due to their high sensitivity, compact size, and low cost. As technology advances, thermistors continue to play a crucial role in areas such as the Internet of Things (IoT), smart homes, and autonomous driving.