In the world of electronic components, temperature sensing and management are crucial. NTC (Negative Temperature Coefficient) and PTC (Positive Temperature Coefficient) thermistors, with their unique temperature-resistance characteristics, have become core components in temperature sensing and control. They play an irreplaceable role in industrial automation, consumer electronics, automotive electronics, and medical devices. This article will provide a comprehensive comparison of these two types of thermistors, covering basic principles, characteristic curves, and application scenarios.

Catalog

III. Temperature-Resistance Characteristic Curves

I. NTC vs. PTC

A thermistor is a type of semiconductor component whose resistance changes significantly with temperature. They are mainly divided into two types: Negative Temperature Coefficient (NTC) and Positive Temperature Coefficient (PTC). NTC thermistors decrease in resistance as temperature rises, making them ideal for high-precision temperature measurement and compensation. PTC thermistors, on the other hand, increase in resistance with rising temperature, and around the Curie point, they exhibit a step-like jump, making them better suited for overcurrent and overheat protection.

II. Work Principles

NTC and PTC thermistors operate on completely different temperature response mechanisms.

· NTC Thermistors: Their operation is based on the negative temperature coefficient property of semiconductor materials. As the temperature increases, the concentration of charge carriers (electrons/holes) inside the material rises, causing resistance to drop exponentially.

· PTC Thermistors: They behave in the opposite way. At low temperatures, PTC thermistors show low resistance. When the temperature exceeds a certain critical point (the Curie temperature), the internal crystal structure changes, the grain boundary potential barrier increases, and the resistance skyrockets by 3–6 orders of magnitude.

III. Temperature-Resistance Characteristic Curves

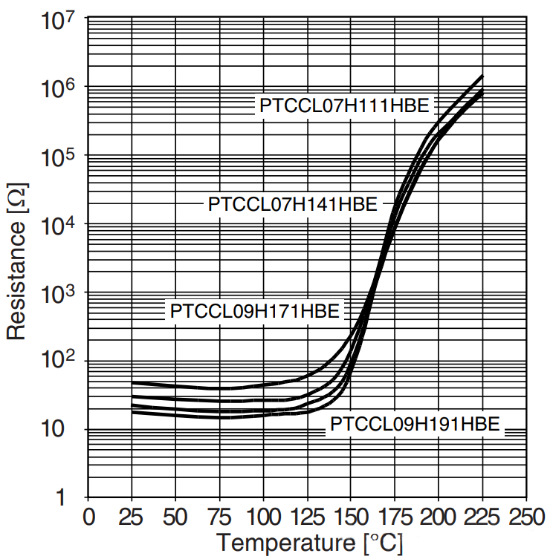

A. PTC Thermistor Temperature vs. Resistance Curve

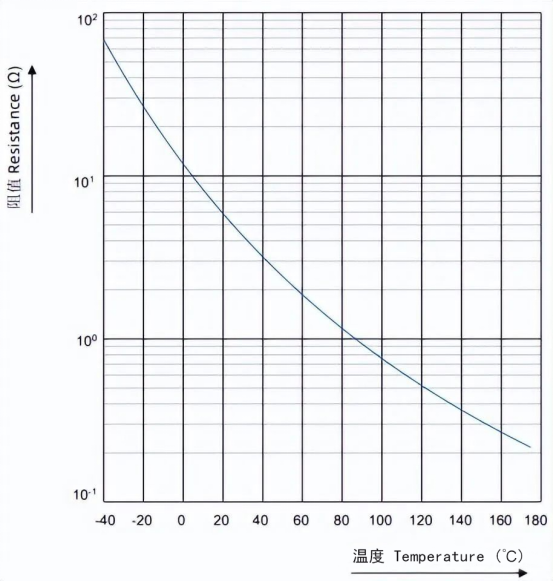

B. NTC Thermistor Temperature vs. Resistance Curve

Looking at the curves, NTC and PTC thermistors exhibit completely different temperature-resistance relationships. NTC thermistors have a smooth negative temperature coefficient curve, with resistance decreasing exponentially as temperature rises. This continuous change across the operating temperature range makes NTC ideal for precise temperature monitoring and control.

In contrast, PTC thermistors display a clear switching characteristic. At lower temperatures, their resistance remains stable. But once the temperature crosses the critical point (Curie temperature), the resistance jumps dramatically, typically increasing by 3–6 orders of magnitude. This sudden change makes PTC thermistors perfect for protective applications, responding quickly under specific temperature conditions.

The temperature coefficients of the two types also differ significantly: NTC thermistors usually range from -3% to -6%/°C, showing a uniform trend, while PTC thermistors can change drastically in the switching region, from +50% to +100%/°C, showing strong non-linearity. This fundamental difference directly determines their respective roles in applications: NTC is mainly for continuous signal-based temperature measurement and compensation, while PTC excels at providing switch-like overcurrent protection and temperature control at critical points.

In real-world use, the linear nature of NTC thermistors provides accurate temperature readings, while the step-like behavior of PTC thermistors makes them ideal for circuit protection. This complementary relationship ensures that both thermistor types hold an indispensable place in the electronics industry.

IV. Applications

· NTC Thermistors: Widely used in temperature measurement, compensation, and surge suppression, such as high-precision temperature monitoring in medical devices or surge current limiting in power inputs.

· PTC Thermistors: Mainly used for overcurrent protection and temperature control, common in motor protection, household appliance overheat protection, and self-resetting fuses.

With the rise of new energy vehicles, both types play important roles in battery thermal management systems: NTC for precise temperature monitoring and PTC for low-temperature heating startup.

V. Conclusion

Although both NTC and PTC thermistors are temperature-sensitive components, their characteristics and applications differ. NTC thermistors, with their continuous negative temperature coefficient, are advantageous in high-precision temperature measurement and compensation. PTC thermistors, with their switch-like behavior, are irreplaceable for circuit protection and temperature control. Engineers need to consider temperature range, precision, response speed, and the application environment when choosing the right thermistor type. With technological advancements, both NTC and PTC thermistors will continue to evolve, providing solid support for the electronics industry.