In the design and production of electronic circuits, the chip inductor serves as a fundamental yet critical passive component, whose performance stability directly affects the efficiency and reliability of the entire circuit. Many engineers and procurement specialists often encounter situations where the measured DC resistance (DCR) of a chip inductor is noticeably higher than expected or exceeds the specifications provided in the datasheet. Elevated resistance not only leads to unnecessary power losses and increased heating but can also cause signal attenuation, reduced power supply efficiency, and even impair the proper functioning of the circuit. This article will systematically explain the basic concept of chip inductors, analyze the common causes of high resistance in detail, and provide practical solutions and preventive measures.

Catalog

II. Main Causes of High Resistance in Chip Inductors

I. What is a Chip Inductor?

A chip inductor, also known as a power chip inductor or surface-mount inductor, is a passive component designed for SMT (Surface-Mount Technology) processes. It is typically composed of a magnetic core (usually made of ferrite or other high-permeability magnetic materials) and a winding (such as copper wire or layered metal traces).

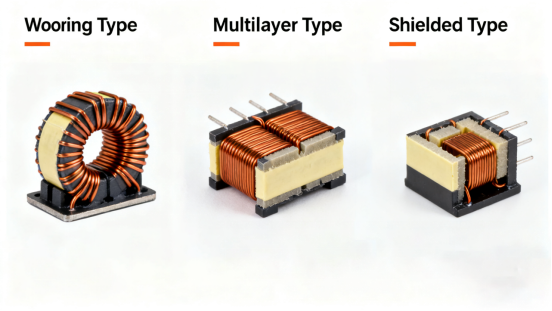

Depending on the structure and manufacturing process, common types of chip inductors include wire-wound, multilayer/laminated, and shielded inductors. Wire-wound chip inductors generally offer a wider inductance range and higher current ratings, making them suitable for power applications; multilayer inductors are better suited for high frequency, compact, and high-density layout scenarios.

In circuits, chip inductors primarily serve roles such as filtering, decoupling, choke, and energy storage. Proper selection, correct soldering, and optimal layout are essential for ensuring their performance stability and system reliability.

II. Main Causes of High Resistance in Chip Inductors

The issue of significantly high resistance in chip inductors can be attributed to several factors, with improper design parameters being a primary cause.

First, an excessive number of turns in the coil leads to a longer current path and increased resistance, resulting in higher DCR—a particularly critical issue in applications requiring low impedance.

Second, if the coil winding direction and number of turns are identical, the current path becomes overly uniform, further increasing resistance and affecting the inductor's frequency response.

Additionally, an overly long coil length is another common cause, as the resistance of a conductor rises with its length—an effect that becomes more pronounced in high frequency environments.

Finally, an insufficient conductor cross-sectional area limits current-carrying capacity, leading to elevated resistance. This often stems from design choices that prioritize miniaturization at the expense of conductive performance.

III. Solutions

To effectively address high resistance in chip inductors, a multi faceted approach involving design, material selection, and production processes is required.

First, during the design phase, the inductor structure should be optimized by carefully selecting parameters such as the number of turns, winding direction, length, and cross sectional area. Environmental factors like temperature, frequency, and load characteristics in the circuit should also be considered to mitigate the risk of high resistance.

Second, high-quality materials should be used. Selecting premium magnetic core and conductor materials can reduce coil resistance, while a multi layer structural design can increase the coil's surface area and improve thermal performance, thereby stabilizing the inductor's resistance.

Third, strengthening production and testing management is crucial. During the manufacturing process, strict control should be maintained over soldering temperature, pad design, and automated placement. Post-production testing—including inductance, impedance, DCR, and Q-factor measurements—should be conducted to promptly identify and analyze abnormal components, ensuring product quality and performance. Through these methods, the risk of high resistance can be effectively reduced, enhancing the reliability of electronic products.

IV. Conclusion

High resistance in chip inductors is a common technical challenge in the electronics manufacturing industry, directly impacting the energy efficiency, stability, and lifespan of end products. By deeply understanding the underlying causes—which span electrical design, material science, and manufacturing processes—we can adopt proactive design optimizations, rigorous supply chain management, and refined production controls to effectively address the issue. Treating DC resistance as a key performance indicator in design and selection, and establishing a comprehensive testing and verification system, can eliminate potential problems at the source. This ensures that electronic components and final products maintain high reliability and superior performance in a competitive market.